Nov 1, 2021

How to build a car

A quick rundown of teams and responsibilities

"Working at Tesla is the hardest job you're ever going to have."

This is the kind of thing I heard all the time from tenured employees when I was first beginning my job at Tesla. I absolutely loved it. A fast-paced culture, cutting-edge tech, and room for innovation on every front. And yes, it was hard...but not for everyone all the time.

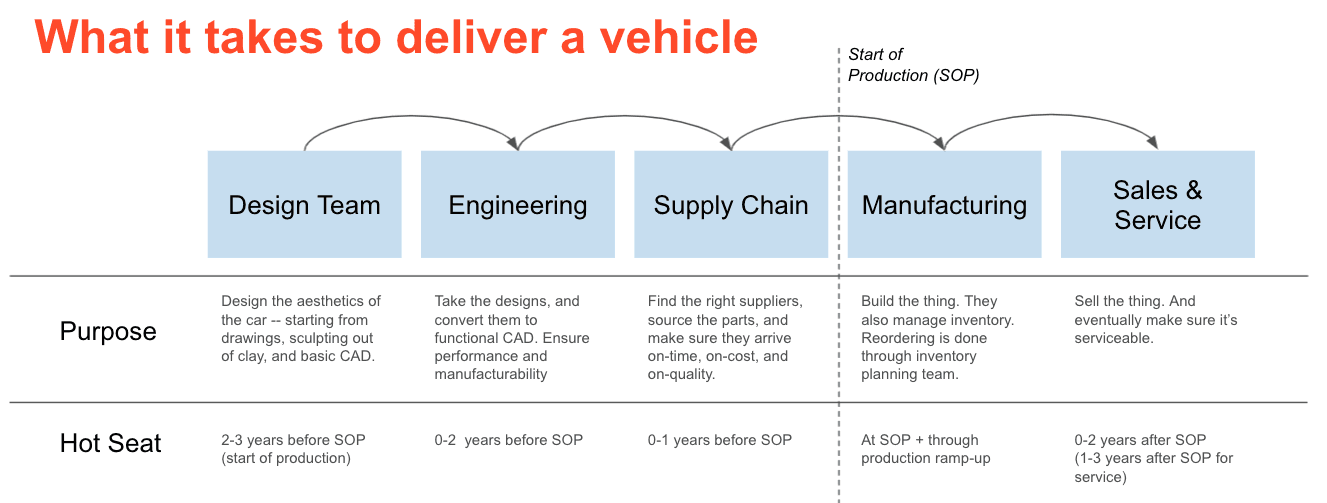

We had this concept of the "hot seat." If your team was in the "hot seat" it meant that you were the mission critical blocker -- and there was likely a mountain of work (and a couple terminations) in the future before things calmed down. When your team was not in the "hot seat" however, it was just a job.

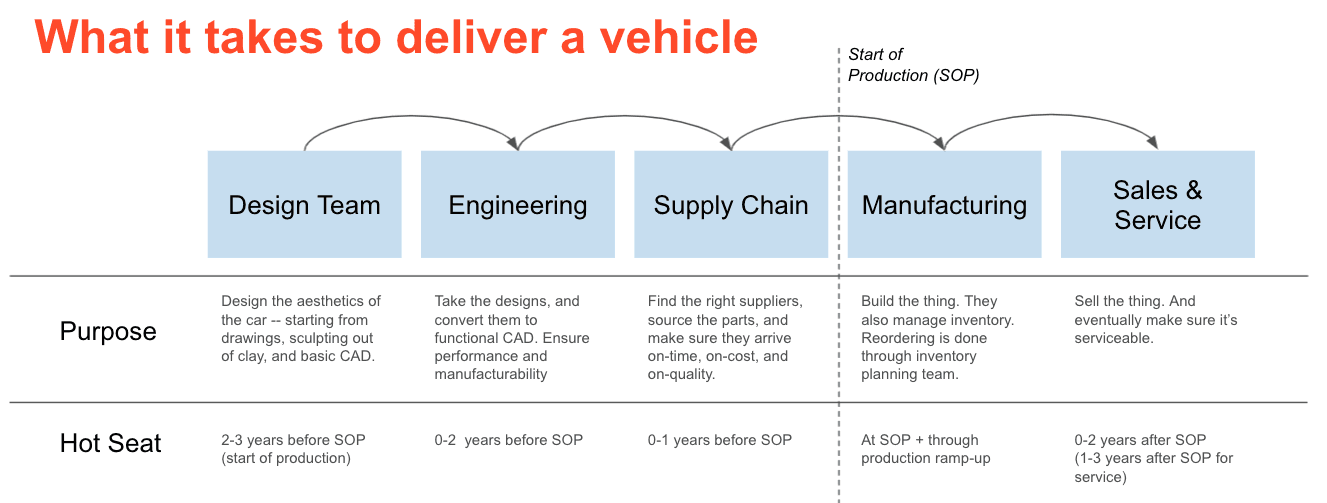

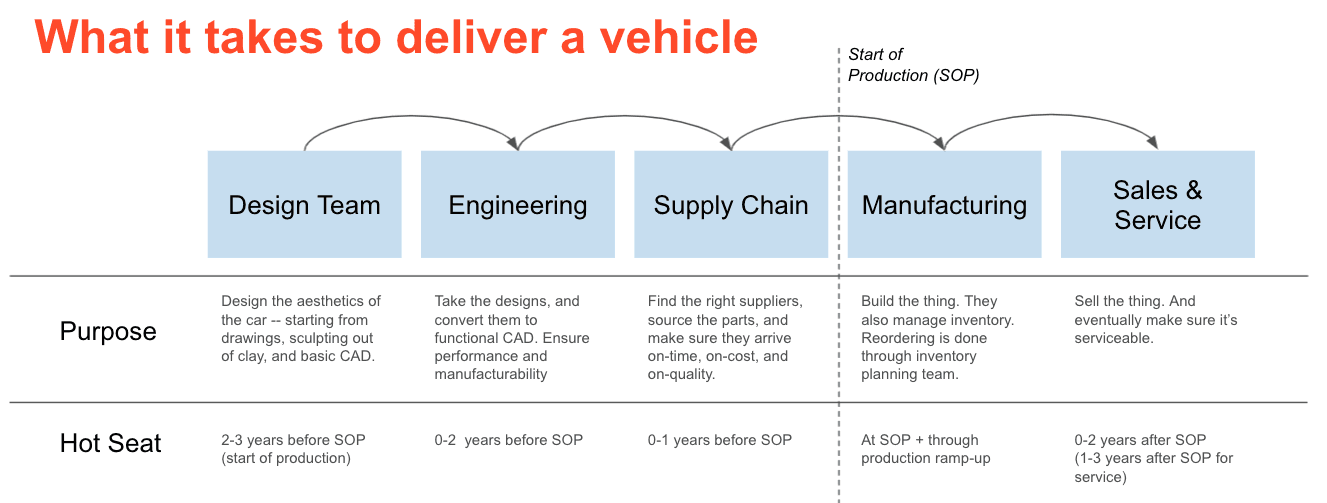

In this post, we will run through a few of the teams involved in bringing a vehicle program from start-through-launch, as well as the periods of time where they're in that critical quarterback position.

In the history of a program, SOP (or start of production) is time = 0. That's metaphorically the year 0 AD, but the creation of a car starts far before that.

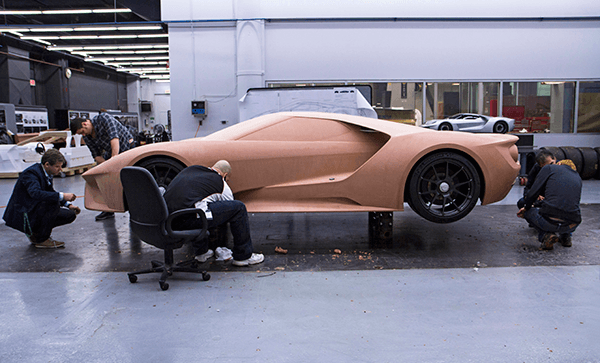

The first team in the "hot seat", 2 to 3 years before SOP is the Design Team. Their responsibility is to work with the executive, sales, and marketing groups to construct a concept for, at the highest-level, what will this car be? Once they have a concept in mind, they'll actually go through the work of clipping graphics, photos, anything that can inspire their aesthetic choices.

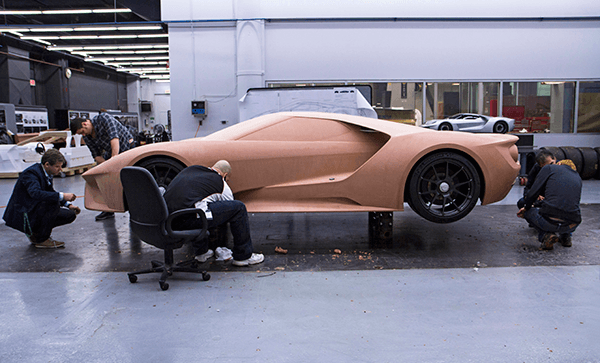

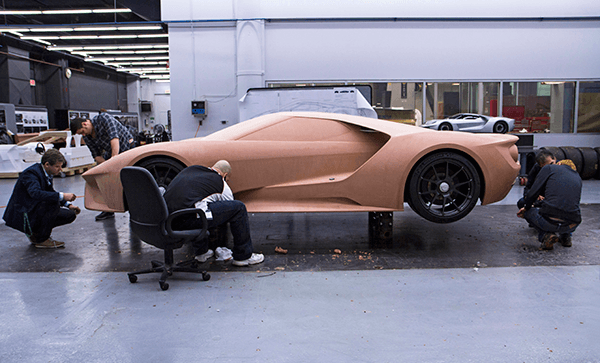

You've probably seen this in the movies, but car designers will actually sculpt an entire 1:1 scale model of the vehicle out of clay before finalizing the design. This is a small, but extremely special group of artists who define the key lines and character of the structure. Typically these clay models will actually get 3D scanned to help inform engineering teams translating those designs in actual engineered parts.

Here's a photo of the design team at Ford sculpting the absolutely delicious Ford GT:

Once the car concept has been finalized (again, typically 2-3 years before SOP), the design team has completed the bulk of their work, and they cede the hot-seat to the Engineering Team.

The Engineering Team's goal is translate the Design Team's concept from idea to reality -- considering a range of attributes like road-worthiness, legal compliance, cost, manufacturability, quality, reliability, and even supplier and material availability.

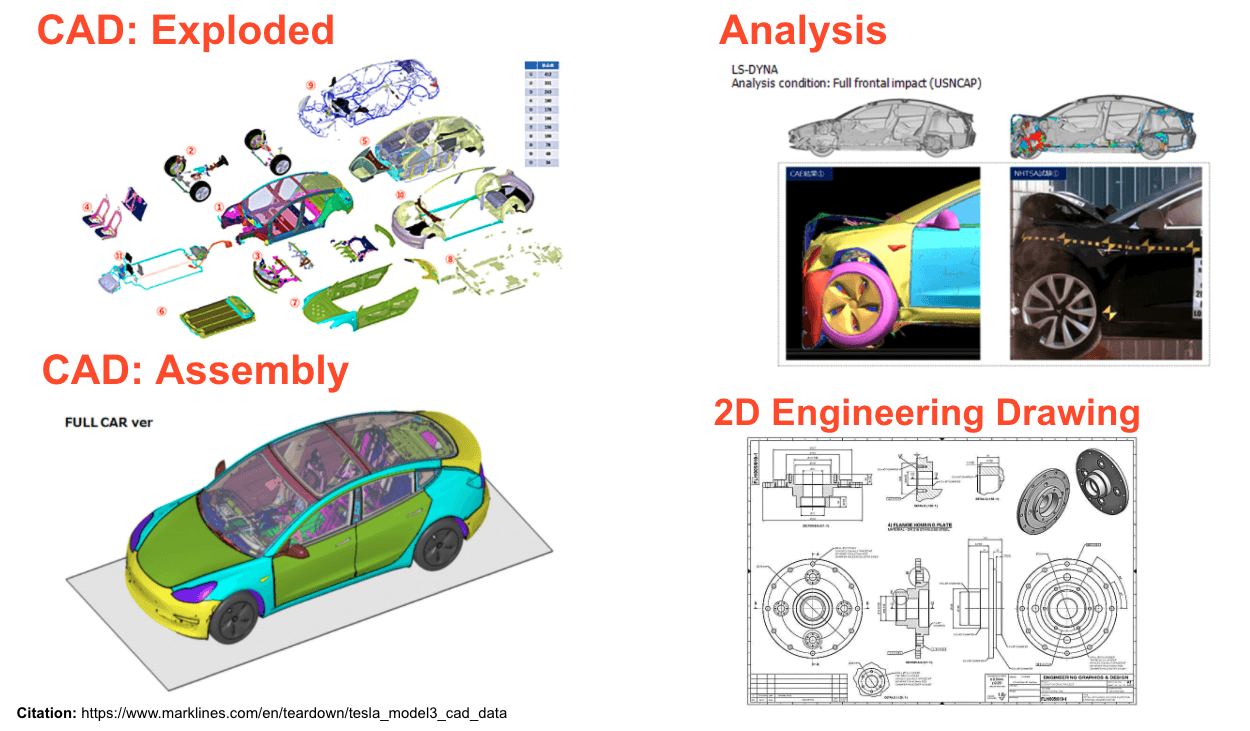

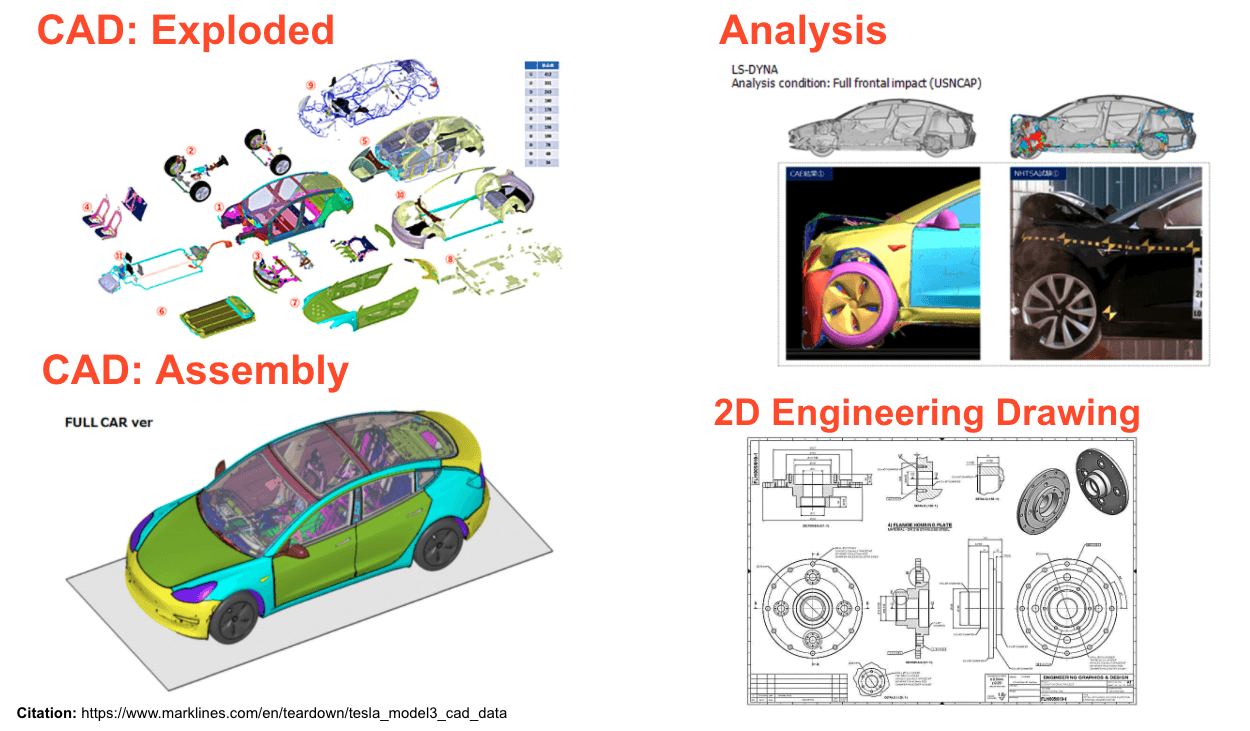

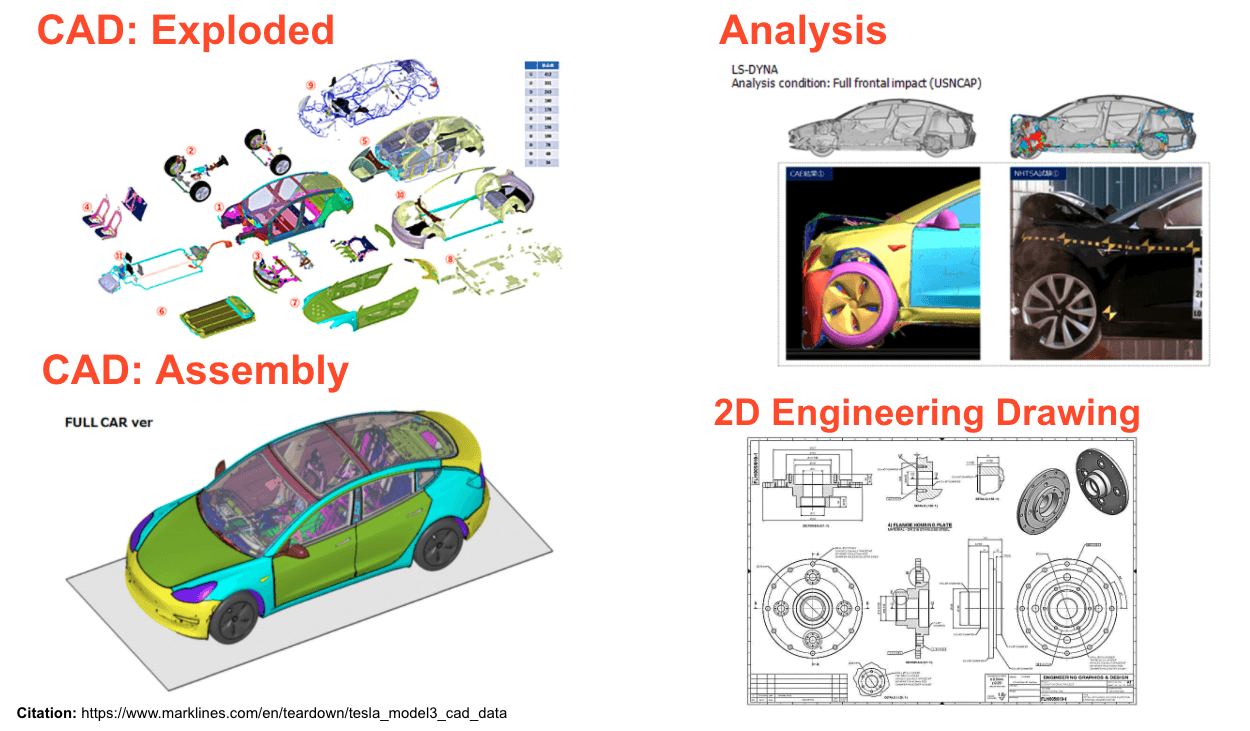

Engineering is in the hot-seat from 2 years before through SOP. The car needs to work, and it's on them. Their initial work product will be a CAD assembly on the computer and accompanying 2D Engineering Drawings. They look something like this:

Engineering itself wears many hats, working through the actual design, to analysis like FEA, body in white stiffness, impact analysis, aerodynamics, mass etc... The 2D drawing is the final output, which shows each part in several different perspectives as well as material and dimension tolerance specs for manufacturing at suppliers.

Once the vehicle is designed and engineered, it's up to the Supply Chain team to source the components, chose the suppliers, and make sure parts get there on-time, on-cost, and on-quality. Procurement is typically in the hot seat the year of SOP.

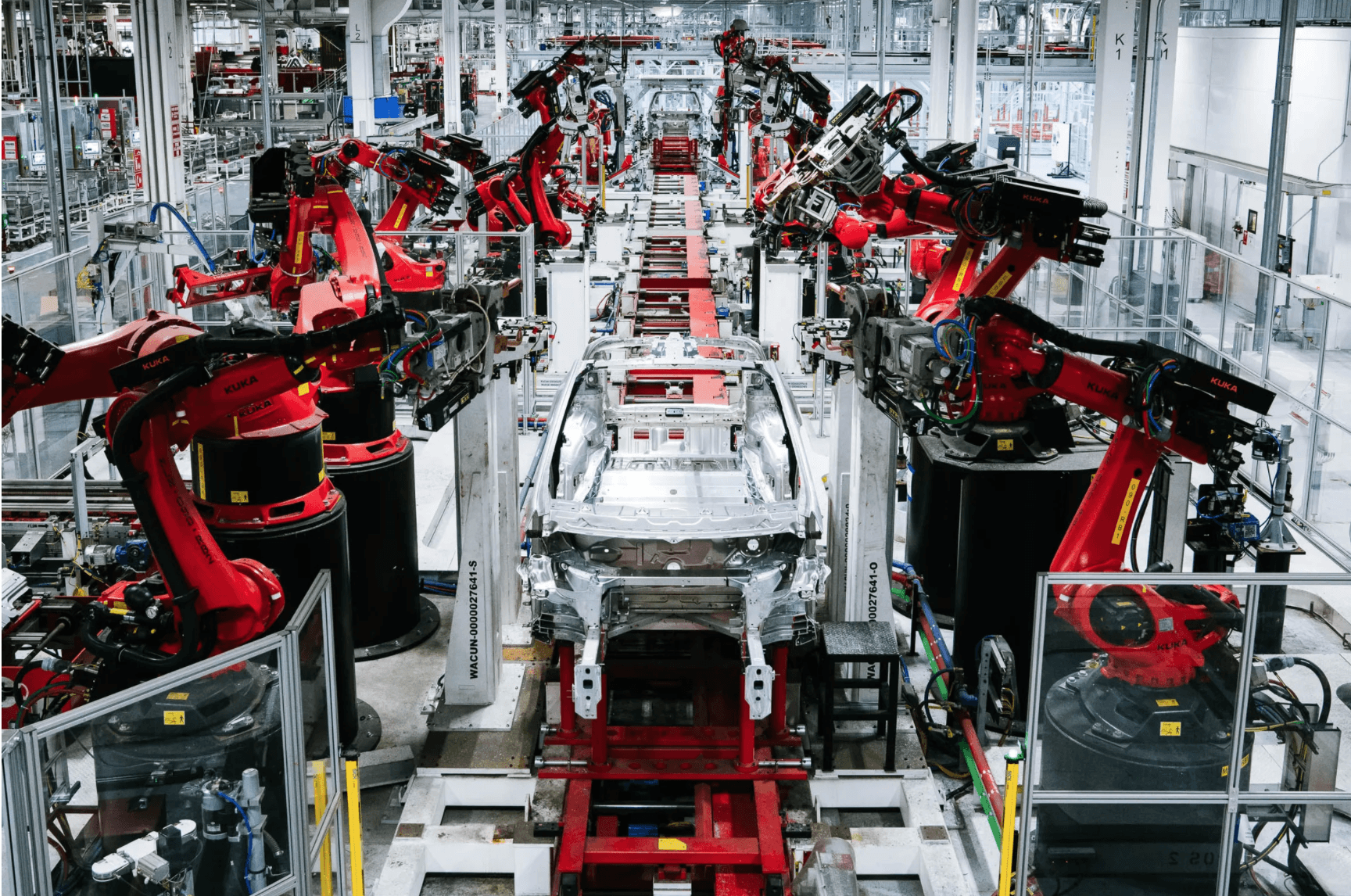

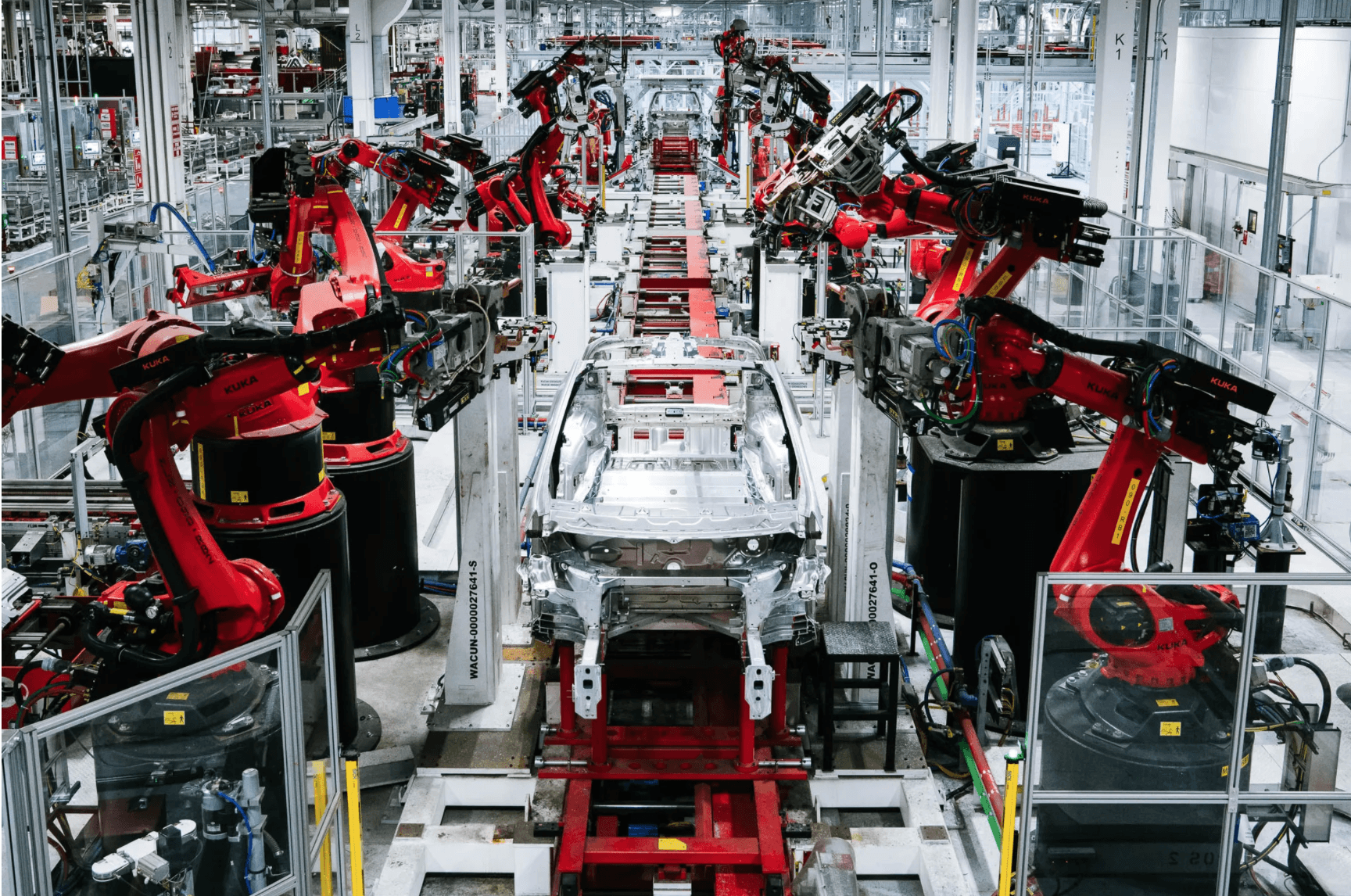

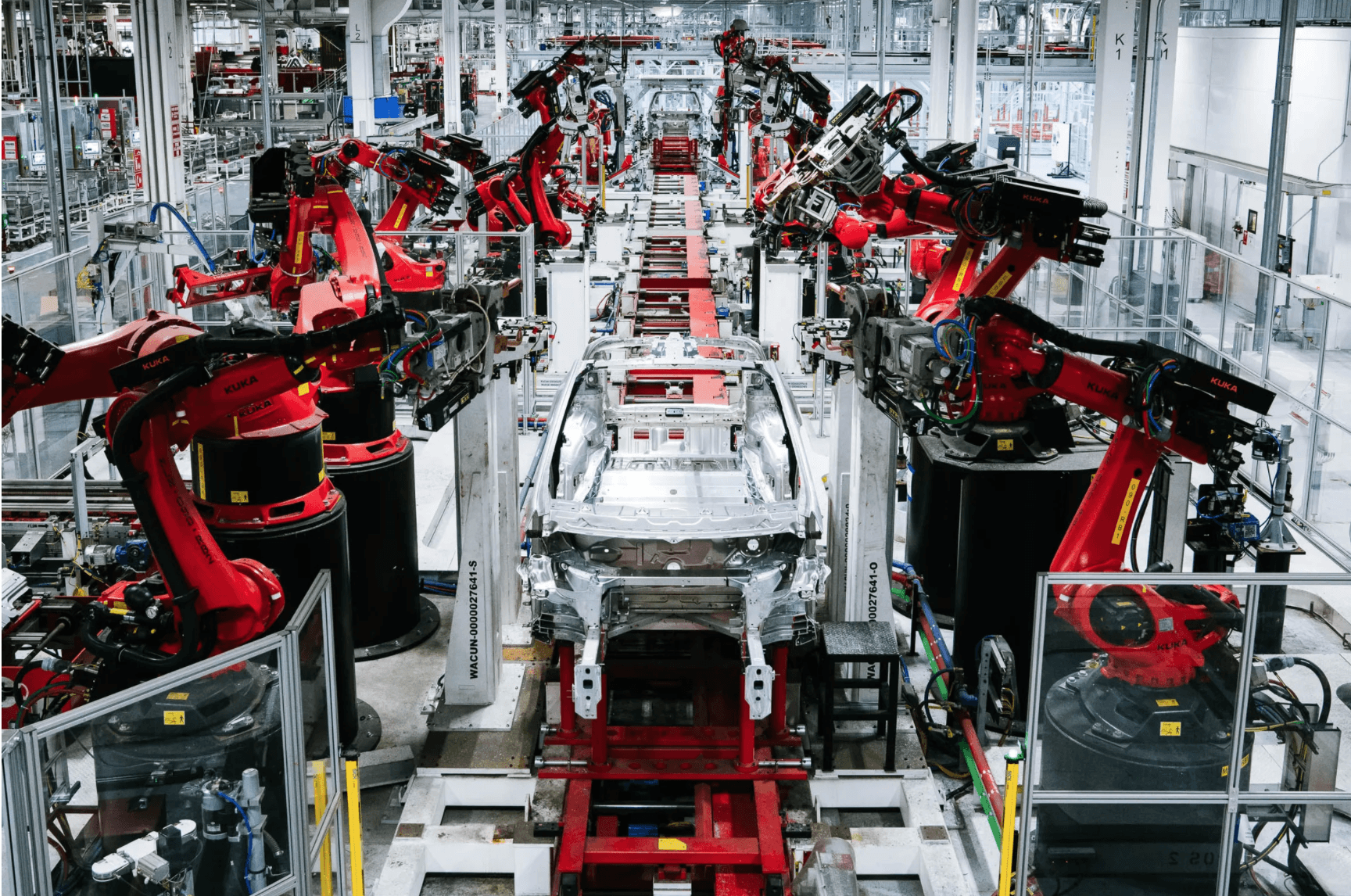

Next up, once the parts arrive it becomes the role of Manufacturing to actually build the vehicle. Remember "Model 3 Production Hell"? For more on that backstory, checkout this article. Manufacturing teams are in the hot seat until the vehicle is being produced consistently at the full run-rate with a high degree of quality and low frequency of reworks.

Finally, once the initial pizzazz of the new vehicle dies down, it's the responsibility of the Sales organization to continue getting in front of customers and bringing in more sales. They're typically in the hot seat around 6 months to 2 years after SOP. And finally, the oft-overlooked Service organization needs to maintain parts and repair the cars, at least through their warranty period, but need to continue supporting paid repairs for decades after SOP.

Pretty simple right?

^ perhaps the most popular meme that floated around regularly during my tenure at Tesla.

Digital tools

Can LightSource help? Yes. It. Can.

Software technologies and e-procurement solutions are extremely important to the top-performing procurement teams. So software like LightSource is an extension of the mind's capabilities, helping give procurement managers superpowers and do things that would normally take months in a matter of minutes.

Digital tools can help on a number of fronts (and with the best tools, all of them at once), including: transparency, cost-reduction, executive visibility, supplier relationships and discovery, and frankly overall procurement team happiness. Basically everything a supply chain manager might need to do in day-to-day life.

Software has this special ability to take the boring transactional tasks off peoples' plates and free up their time and attention to focus on the hard strategic or relationship questions that procurement professionals just love.

If you have any questions about LightSource or want to talk procurement generally, don't hesitate to reach out at: contact@lightsource.ai

"Working at Tesla is the hardest job you're ever going to have."

This is the kind of thing I heard all the time from tenured employees when I was first beginning my job at Tesla. I absolutely loved it. A fast-paced culture, cutting-edge tech, and room for innovation on every front. And yes, it was hard...but not for everyone all the time.

We had this concept of the "hot seat." If your team was in the "hot seat" it meant that you were the mission critical blocker -- and there was likely a mountain of work (and a couple terminations) in the future before things calmed down. When your team was not in the "hot seat" however, it was just a job.

In this post, we will run through a few of the teams involved in bringing a vehicle program from start-through-launch, as well as the periods of time where they're in that critical quarterback position.

In the history of a program, SOP (or start of production) is time = 0. That's metaphorically the year 0 AD, but the creation of a car starts far before that.

The first team in the "hot seat", 2 to 3 years before SOP is the Design Team. Their responsibility is to work with the executive, sales, and marketing groups to construct a concept for, at the highest-level, what will this car be? Once they have a concept in mind, they'll actually go through the work of clipping graphics, photos, anything that can inspire their aesthetic choices.

You've probably seen this in the movies, but car designers will actually sculpt an entire 1:1 scale model of the vehicle out of clay before finalizing the design. This is a small, but extremely special group of artists who define the key lines and character of the structure. Typically these clay models will actually get 3D scanned to help inform engineering teams translating those designs in actual engineered parts.

Here's a photo of the design team at Ford sculpting the absolutely delicious Ford GT:

Once the car concept has been finalized (again, typically 2-3 years before SOP), the design team has completed the bulk of their work, and they cede the hot-seat to the Engineering Team.

The Engineering Team's goal is translate the Design Team's concept from idea to reality -- considering a range of attributes like road-worthiness, legal compliance, cost, manufacturability, quality, reliability, and even supplier and material availability.

Engineering is in the hot-seat from 2 years before through SOP. The car needs to work, and it's on them. Their initial work product will be a CAD assembly on the computer and accompanying 2D Engineering Drawings. They look something like this:

Engineering itself wears many hats, working through the actual design, to analysis like FEA, body in white stiffness, impact analysis, aerodynamics, mass etc... The 2D drawing is the final output, which shows each part in several different perspectives as well as material and dimension tolerance specs for manufacturing at suppliers.

Once the vehicle is designed and engineered, it's up to the Supply Chain team to source the components, chose the suppliers, and make sure parts get there on-time, on-cost, and on-quality. Procurement is typically in the hot seat the year of SOP.

Next up, once the parts arrive it becomes the role of Manufacturing to actually build the vehicle. Remember "Model 3 Production Hell"? For more on that backstory, checkout this article. Manufacturing teams are in the hot seat until the vehicle is being produced consistently at the full run-rate with a high degree of quality and low frequency of reworks.

Finally, once the initial pizzazz of the new vehicle dies down, it's the responsibility of the Sales organization to continue getting in front of customers and bringing in more sales. They're typically in the hot seat around 6 months to 2 years after SOP. And finally, the oft-overlooked Service organization needs to maintain parts and repair the cars, at least through their warranty period, but need to continue supporting paid repairs for decades after SOP.

Pretty simple right?

^ perhaps the most popular meme that floated around regularly during my tenure at Tesla.

Digital tools

Can LightSource help? Yes. It. Can.

Software technologies and e-procurement solutions are extremely important to the top-performing procurement teams. So software like LightSource is an extension of the mind's capabilities, helping give procurement managers superpowers and do things that would normally take months in a matter of minutes.

Digital tools can help on a number of fronts (and with the best tools, all of them at once), including: transparency, cost-reduction, executive visibility, supplier relationships and discovery, and frankly overall procurement team happiness. Basically everything a supply chain manager might need to do in day-to-day life.

Software has this special ability to take the boring transactional tasks off peoples' plates and free up their time and attention to focus on the hard strategic or relationship questions that procurement professionals just love.

If you have any questions about LightSource or want to talk procurement generally, don't hesitate to reach out at: contact@lightsource.ai

"Working at Tesla is the hardest job you're ever going to have."

This is the kind of thing I heard all the time from tenured employees when I was first beginning my job at Tesla. I absolutely loved it. A fast-paced culture, cutting-edge tech, and room for innovation on every front. And yes, it was hard...but not for everyone all the time.

We had this concept of the "hot seat." If your team was in the "hot seat" it meant that you were the mission critical blocker -- and there was likely a mountain of work (and a couple terminations) in the future before things calmed down. When your team was not in the "hot seat" however, it was just a job.

In this post, we will run through a few of the teams involved in bringing a vehicle program from start-through-launch, as well as the periods of time where they're in that critical quarterback position.

In the history of a program, SOP (or start of production) is time = 0. That's metaphorically the year 0 AD, but the creation of a car starts far before that.

The first team in the "hot seat", 2 to 3 years before SOP is the Design Team. Their responsibility is to work with the executive, sales, and marketing groups to construct a concept for, at the highest-level, what will this car be? Once they have a concept in mind, they'll actually go through the work of clipping graphics, photos, anything that can inspire their aesthetic choices.

You've probably seen this in the movies, but car designers will actually sculpt an entire 1:1 scale model of the vehicle out of clay before finalizing the design. This is a small, but extremely special group of artists who define the key lines and character of the structure. Typically these clay models will actually get 3D scanned to help inform engineering teams translating those designs in actual engineered parts.

Here's a photo of the design team at Ford sculpting the absolutely delicious Ford GT:

Once the car concept has been finalized (again, typically 2-3 years before SOP), the design team has completed the bulk of their work, and they cede the hot-seat to the Engineering Team.

The Engineering Team's goal is translate the Design Team's concept from idea to reality -- considering a range of attributes like road-worthiness, legal compliance, cost, manufacturability, quality, reliability, and even supplier and material availability.

Engineering is in the hot-seat from 2 years before through SOP. The car needs to work, and it's on them. Their initial work product will be a CAD assembly on the computer and accompanying 2D Engineering Drawings. They look something like this:

Engineering itself wears many hats, working through the actual design, to analysis like FEA, body in white stiffness, impact analysis, aerodynamics, mass etc... The 2D drawing is the final output, which shows each part in several different perspectives as well as material and dimension tolerance specs for manufacturing at suppliers.

Once the vehicle is designed and engineered, it's up to the Supply Chain team to source the components, chose the suppliers, and make sure parts get there on-time, on-cost, and on-quality. Procurement is typically in the hot seat the year of SOP.

Next up, once the parts arrive it becomes the role of Manufacturing to actually build the vehicle. Remember "Model 3 Production Hell"? For more on that backstory, checkout this article. Manufacturing teams are in the hot seat until the vehicle is being produced consistently at the full run-rate with a high degree of quality and low frequency of reworks.

Finally, once the initial pizzazz of the new vehicle dies down, it's the responsibility of the Sales organization to continue getting in front of customers and bringing in more sales. They're typically in the hot seat around 6 months to 2 years after SOP. And finally, the oft-overlooked Service organization needs to maintain parts and repair the cars, at least through their warranty period, but need to continue supporting paid repairs for decades after SOP.

Pretty simple right?

^ perhaps the most popular meme that floated around regularly during my tenure at Tesla.

Digital tools

Can LightSource help? Yes. It. Can.

Software technologies and e-procurement solutions are extremely important to the top-performing procurement teams. So software like LightSource is an extension of the mind's capabilities, helping give procurement managers superpowers and do things that would normally take months in a matter of minutes.

Digital tools can help on a number of fronts (and with the best tools, all of them at once), including: transparency, cost-reduction, executive visibility, supplier relationships and discovery, and frankly overall procurement team happiness. Basically everything a supply chain manager might need to do in day-to-day life.

Software has this special ability to take the boring transactional tasks off peoples' plates and free up their time and attention to focus on the hard strategic or relationship questions that procurement professionals just love.

If you have any questions about LightSource or want to talk procurement generally, don't hesitate to reach out at: contact@lightsource.ai

Ready to change the way you source?

Try out LightSource and you’ll never go back to Excel and email.

Ready to change the way you source?

Try out LightSource and you’ll never go back to Excel and email.

Ready to change the way you source?

Try out LightSource and you’ll never go back to Excel and email.

Trusted by:

Trusted by:

Trusted by:

*GARTNER is a registered trademark and service mark of Gartner, Inc. and/or its affiliates in the U.S. and internationally, and COOL VENDORS is a registered trademark of Gartner, Inc. and/or its affiliates and are used herein with permission. All rights reserved. Gartner does not endorse any vendor, product or service depicted in its research publications, and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner’s research organization and should not be construed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose.