Dec 5, 2022

White paper: Inflation gate

by Sourav Das Adhikari at LightSource

No – there isn’t a silver bullet, but in this article we detail a few approaches our customers have used to achieve impact against all odds.

Inflationary pressures keep mounting on procurement leaders as they scramble to keep costs under control. In addition, supply shortages in select commodities appear almost weekly, adding fire-fighting to already full plates. Furthermore, trade pressures hinder companies trying to do business effectively in foreign countries. Here we’re painting a grim but also decisively interesting time for procurement. And even still, the best procurement leaders are innovating their strategies and going on the offensive. However, the effectiveness of individual strategies varies vastly based on the industry, historic operating practices, region, market power etc.

Select strategies below have been successfully implemented by procurement leaders to contain:

Ride the index

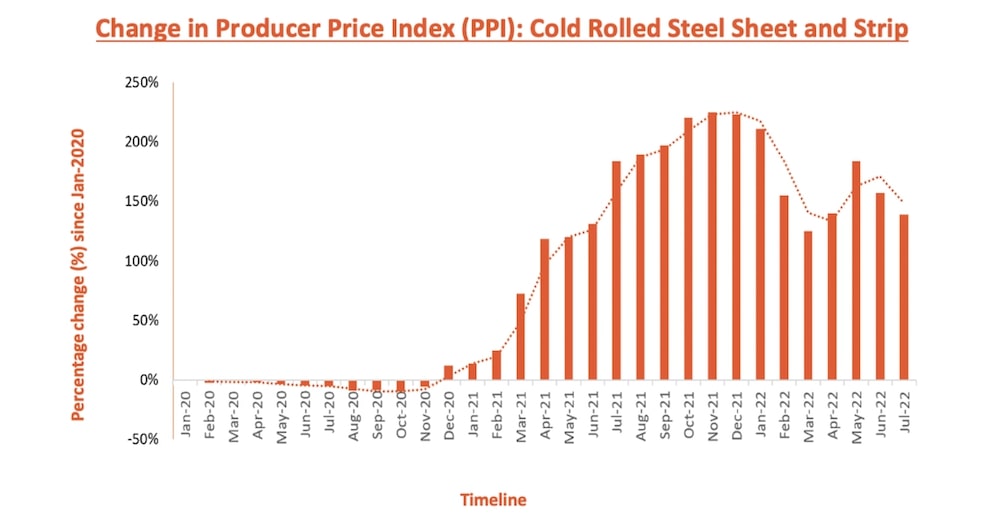

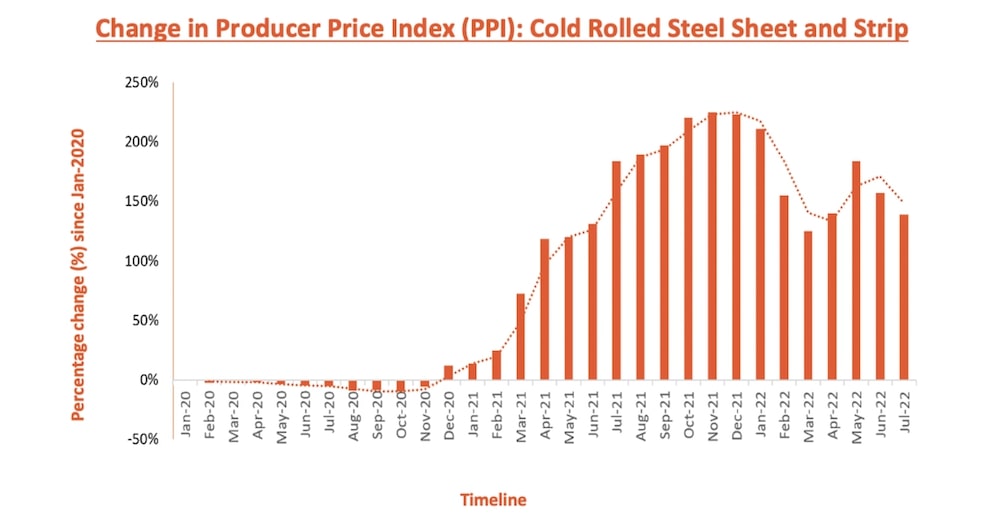

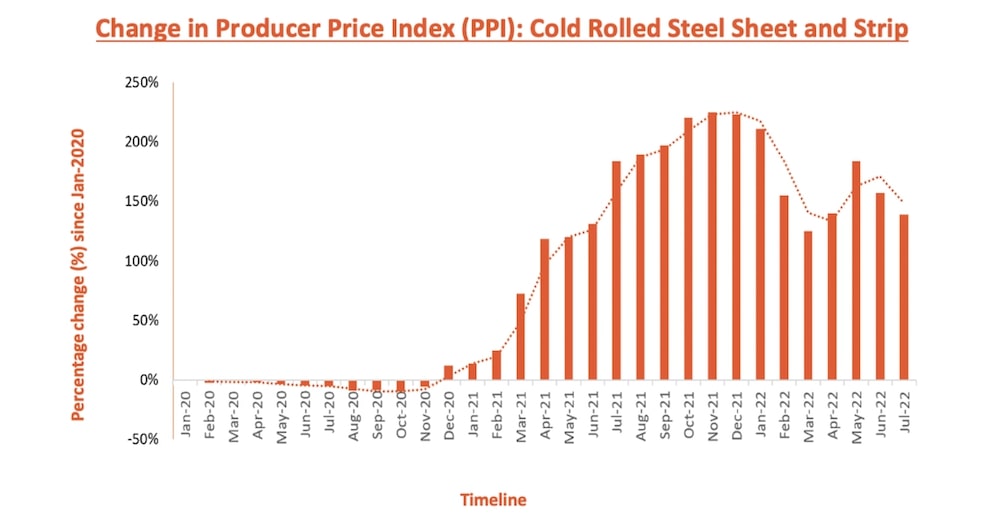

As the index for some commodities have moved away for the peak and is headed downwards, several companies have opted for index-based price flexibility in their contracts. Procurement leaders are using e-sourcing solutions to periodically launch price updates with suppliers especially for parts that are closely tied to index price such as wood products, metal fabricated parts, resin-based products etc. This technique helps to monitor price changes in a dashboard across all parts and execute price changes with suppliers periodically. Example of index prices for ‘Cold Rolled Steel Sheet’ where companies can ‘Ride the index’.

Case study 1: An automotive company segmented, and prioritized categories affected by inflation. Then the category managers tracked index on a weekly basis. As the index prices were approaching peak, category managers sent requests for periodic price updates from suppliers using our sourcing solution. This helped buyers to view price changes and lock-in prices when the underlying index prices were trending down.

Reduce SKU complexity – This is a commonly known concept in the procurement world.

Reduce SKU complexity – This is a commonly known concept in the procurement world. But few procurement leaders have actively pursued complexity reduction. However, the current business situation is a ‘trigger’ to work on reducing SKU complexity. Several leaders are actively working to reduce SKU complexity for 2 reasons:

a. Contain cost increases: Companies are consolidating SKUs to increase volume for select SKUs. This helps suppliers to focus on their supply chain while potentially providing price advantages to the buyers.

b. Manage supply risks: Companies are also shifting volume to SKUs which are not affected by supply shortages

Case study 2: With rising prices across several sheet metal parts, an automotive manufacturer decided on a strategy which was different from supplier negotiations. The company collaborated with the supplier to develop a strategy for part consolidation which would help the buyer to contain prices and would help the supplier to streamline their supply chain and capacity planning.

Continue sourcing post -pandemic

Procurement leaders are amazed at prices that non-incumbent suppliers are providing for categories that haven’t been sourced during pandemic. In several categories, procurement leaders are not only able to contain costs but are also able to get savings. Although, the savings realized in this market is typically not close to savings that you would expect in a non-inflationary environment.

Case study 3: An industrial company wanted to source MRO as the incumbent was providing 30% price increase. Conducting an RFQ with multiple suppliers using our sourcing solution identified upto 8% savings in Round 1 from multiple suppliers. Seeing this difference gave confidence to the category manager that they don’t have to take price increases from the incumbent but just move to other suppliers if incumbent continues to propose price increase.

Onshoring

With the recent risks of supply disruptions and uncertainties in trade environment, business leaders are reviewing on-shoring or near shoring to manage risks. For select categories/ industries, the onshore market has disappeared because of continuous prior off-shoring practices. Hence, some procurement leaders are evaluating whether they can invest in on-shore/ near-shore supplier capabilities for a mid-long term relationship.

Market-cost/ should-cost based negotiations

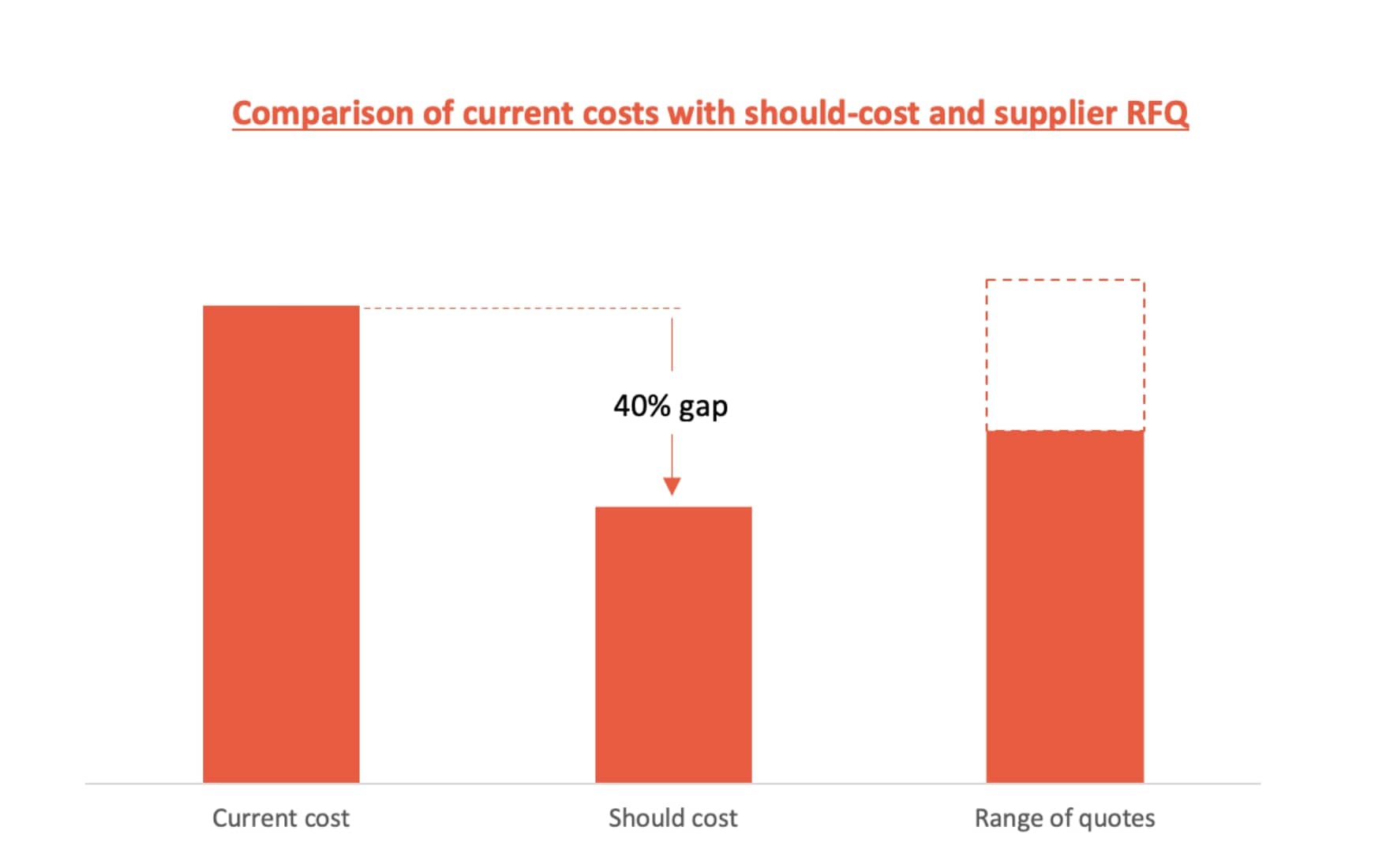

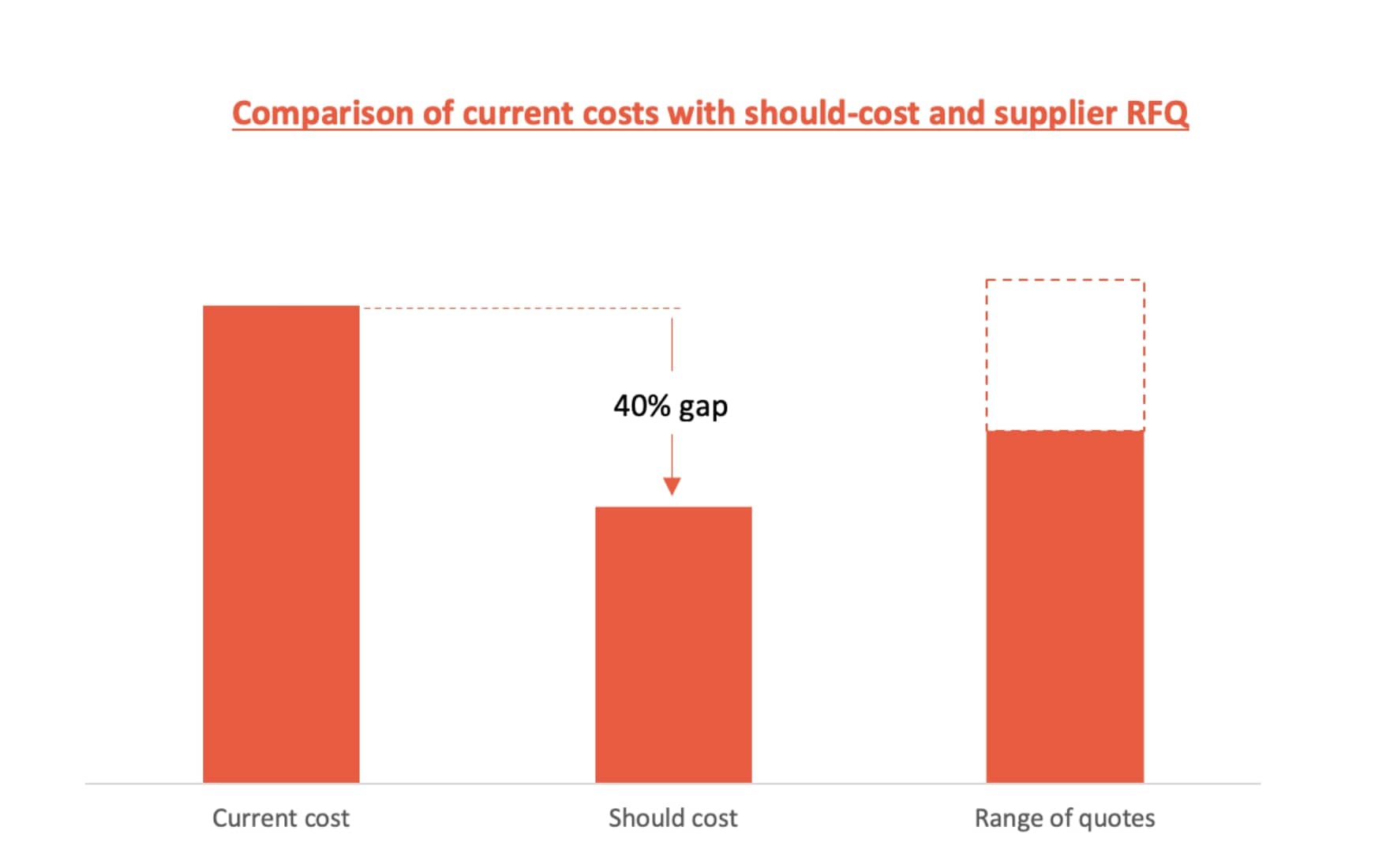

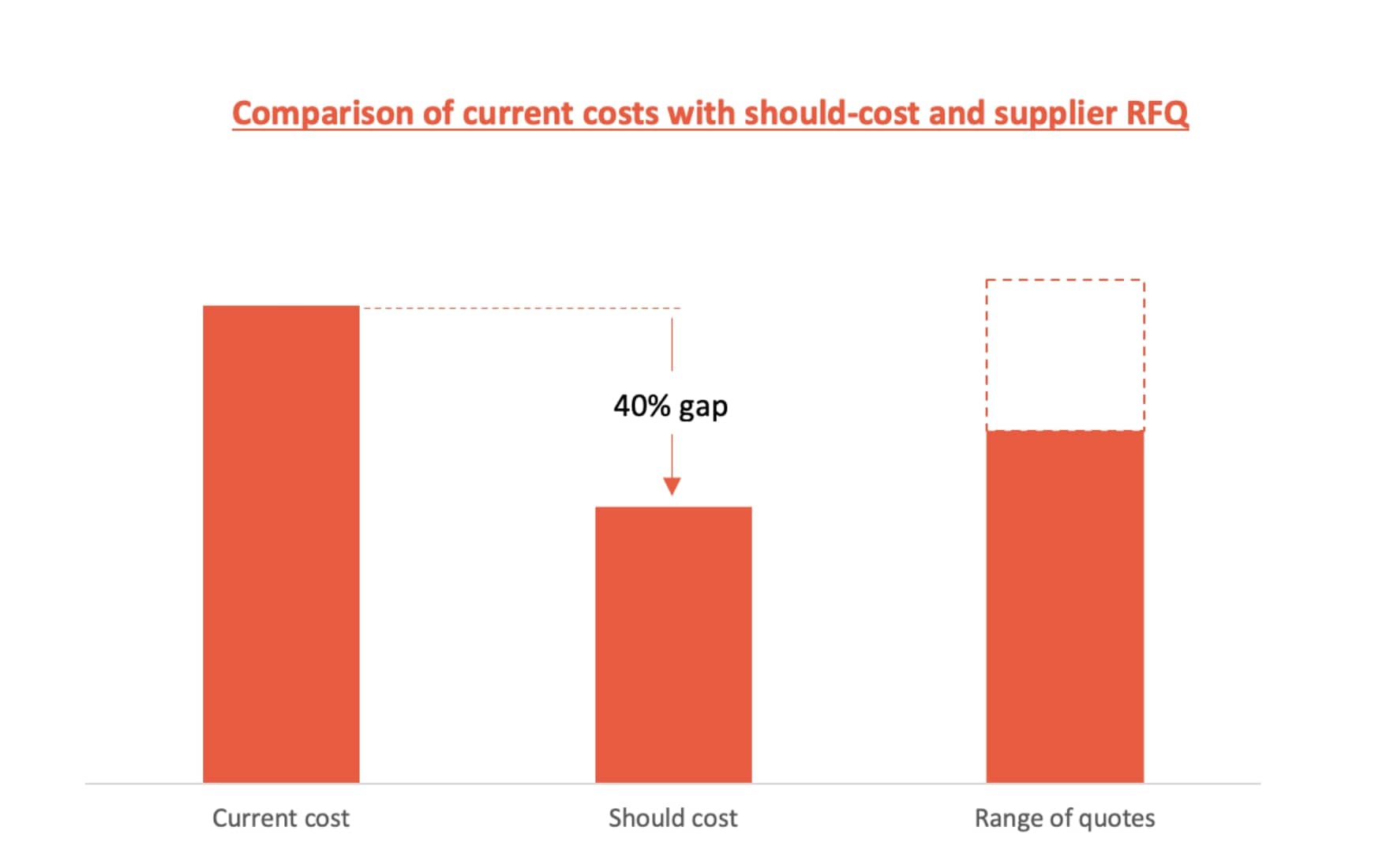

Market-cost/ should-cost based negotiations – The pressure to reduce costs in the fiscal year often pushed procurement leaders to conduct negotiations with incumbents in an inflationary environment. Should-costing was one of the critical methods which helped procurement leaders identify the parameters that can be negotiated with the incumbents, and determine the floor and ceiling for such negotiations. The should-costs were further validated by either direct sourcing or insights from an adjacent category sourcing to finalize the opportunities.

Case study 4: A food packaging company was unsure of the current market conditions and what should they expect from a pricing standpoint. The category manager conducted should-cost analysis for high runner parts and found a 40% gap between current price and should-cost. The should-cost was further validated by a sourcing effort where several suppliers were able to bridge 50% of the should cost gap hence giving 20%+ savings on the high runners.

Make vs buy

Business leaders are continually evaluating make vs buy for products manufactured internally. This helps companies to manage supply risks while only outsourcing those products which are not-competitive to manufacture internally.

The company decided to outsource 40% of the volume to suppliers and keep 60% of the volume internally

Case study 5: An automotive company wanted to outsource stamped parts. However, the company also had an internal stamping operation. Hence the company conducted an RFQ with different suppliers and continually compared internal operations. Overall, the company decided to outsource 40% of the volume to suppliers and keep 60% of the volume internally.

Adopt next-generation technologies

The impact of software across all business functions has been nothing short of revolutionary over the past several decades. Yet somehow, procurement is still underserved by high-quality tools with a friendly user experience. As a result, teams often default back to excel and email (unless they’re forced to use a clunky and brittle SAP installation).

LightSource is radically different, and what many are calling the “next-generation operating system for procurement teams.” With enough time and talent, all of the 6 strategies above are approachable. However, in a world with limited resources, software tools like LightSource empower procurement to do more, be more strategic, while conserving their bandwidth. We work with customers hand-in-hand to effectively implement LightSource, help in developing category strategy and manage the sourcing process as needed. LightSource solution comes with an excellent ‘white glove procurement concierge service’ that is the best combination of software and services in the market.

No – there isn’t a silver bullet, but in this article we detail a few approaches our customers have used to achieve impact against all odds.

Inflationary pressures keep mounting on procurement leaders as they scramble to keep costs under control. In addition, supply shortages in select commodities appear almost weekly, adding fire-fighting to already full plates. Furthermore, trade pressures hinder companies trying to do business effectively in foreign countries. Here we’re painting a grim but also decisively interesting time for procurement. And even still, the best procurement leaders are innovating their strategies and going on the offensive. However, the effectiveness of individual strategies varies vastly based on the industry, historic operating practices, region, market power etc.

Select strategies below have been successfully implemented by procurement leaders to contain:

Ride the index

As the index for some commodities have moved away for the peak and is headed downwards, several companies have opted for index-based price flexibility in their contracts. Procurement leaders are using e-sourcing solutions to periodically launch price updates with suppliers especially for parts that are closely tied to index price such as wood products, metal fabricated parts, resin-based products etc. This technique helps to monitor price changes in a dashboard across all parts and execute price changes with suppliers periodically. Example of index prices for ‘Cold Rolled Steel Sheet’ where companies can ‘Ride the index’.

Case study 1: An automotive company segmented, and prioritized categories affected by inflation. Then the category managers tracked index on a weekly basis. As the index prices were approaching peak, category managers sent requests for periodic price updates from suppliers using our sourcing solution. This helped buyers to view price changes and lock-in prices when the underlying index prices were trending down.

Reduce SKU complexity – This is a commonly known concept in the procurement world.

Reduce SKU complexity – This is a commonly known concept in the procurement world. But few procurement leaders have actively pursued complexity reduction. However, the current business situation is a ‘trigger’ to work on reducing SKU complexity. Several leaders are actively working to reduce SKU complexity for 2 reasons:

a. Contain cost increases: Companies are consolidating SKUs to increase volume for select SKUs. This helps suppliers to focus on their supply chain while potentially providing price advantages to the buyers.

b. Manage supply risks: Companies are also shifting volume to SKUs which are not affected by supply shortages

Case study 2: With rising prices across several sheet metal parts, an automotive manufacturer decided on a strategy which was different from supplier negotiations. The company collaborated with the supplier to develop a strategy for part consolidation which would help the buyer to contain prices and would help the supplier to streamline their supply chain and capacity planning.

Continue sourcing post -pandemic

Procurement leaders are amazed at prices that non-incumbent suppliers are providing for categories that haven’t been sourced during pandemic. In several categories, procurement leaders are not only able to contain costs but are also able to get savings. Although, the savings realized in this market is typically not close to savings that you would expect in a non-inflationary environment.

Case study 3: An industrial company wanted to source MRO as the incumbent was providing 30% price increase. Conducting an RFQ with multiple suppliers using our sourcing solution identified upto 8% savings in Round 1 from multiple suppliers. Seeing this difference gave confidence to the category manager that they don’t have to take price increases from the incumbent but just move to other suppliers if incumbent continues to propose price increase.

Onshoring

With the recent risks of supply disruptions and uncertainties in trade environment, business leaders are reviewing on-shoring or near shoring to manage risks. For select categories/ industries, the onshore market has disappeared because of continuous prior off-shoring practices. Hence, some procurement leaders are evaluating whether they can invest in on-shore/ near-shore supplier capabilities for a mid-long term relationship.

Market-cost/ should-cost based negotiations

Market-cost/ should-cost based negotiations – The pressure to reduce costs in the fiscal year often pushed procurement leaders to conduct negotiations with incumbents in an inflationary environment. Should-costing was one of the critical methods which helped procurement leaders identify the parameters that can be negotiated with the incumbents, and determine the floor and ceiling for such negotiations. The should-costs were further validated by either direct sourcing or insights from an adjacent category sourcing to finalize the opportunities.

Case study 4: A food packaging company was unsure of the current market conditions and what should they expect from a pricing standpoint. The category manager conducted should-cost analysis for high runner parts and found a 40% gap between current price and should-cost. The should-cost was further validated by a sourcing effort where several suppliers were able to bridge 50% of the should cost gap hence giving 20%+ savings on the high runners.

Make vs buy

Business leaders are continually evaluating make vs buy for products manufactured internally. This helps companies to manage supply risks while only outsourcing those products which are not-competitive to manufacture internally.

The company decided to outsource 40% of the volume to suppliers and keep 60% of the volume internally

Case study 5: An automotive company wanted to outsource stamped parts. However, the company also had an internal stamping operation. Hence the company conducted an RFQ with different suppliers and continually compared internal operations. Overall, the company decided to outsource 40% of the volume to suppliers and keep 60% of the volume internally.

Adopt next-generation technologies

The impact of software across all business functions has been nothing short of revolutionary over the past several decades. Yet somehow, procurement is still underserved by high-quality tools with a friendly user experience. As a result, teams often default back to excel and email (unless they’re forced to use a clunky and brittle SAP installation).

LightSource is radically different, and what many are calling the “next-generation operating system for procurement teams.” With enough time and talent, all of the 6 strategies above are approachable. However, in a world with limited resources, software tools like LightSource empower procurement to do more, be more strategic, while conserving their bandwidth. We work with customers hand-in-hand to effectively implement LightSource, help in developing category strategy and manage the sourcing process as needed. LightSource solution comes with an excellent ‘white glove procurement concierge service’ that is the best combination of software and services in the market.

No – there isn’t a silver bullet, but in this article we detail a few approaches our customers have used to achieve impact against all odds.

Inflationary pressures keep mounting on procurement leaders as they scramble to keep costs under control. In addition, supply shortages in select commodities appear almost weekly, adding fire-fighting to already full plates. Furthermore, trade pressures hinder companies trying to do business effectively in foreign countries. Here we’re painting a grim but also decisively interesting time for procurement. And even still, the best procurement leaders are innovating their strategies and going on the offensive. However, the effectiveness of individual strategies varies vastly based on the industry, historic operating practices, region, market power etc.

Select strategies below have been successfully implemented by procurement leaders to contain:

Ride the index

As the index for some commodities have moved away for the peak and is headed downwards, several companies have opted for index-based price flexibility in their contracts. Procurement leaders are using e-sourcing solutions to periodically launch price updates with suppliers especially for parts that are closely tied to index price such as wood products, metal fabricated parts, resin-based products etc. This technique helps to monitor price changes in a dashboard across all parts and execute price changes with suppliers periodically. Example of index prices for ‘Cold Rolled Steel Sheet’ where companies can ‘Ride the index’.

Case study 1: An automotive company segmented, and prioritized categories affected by inflation. Then the category managers tracked index on a weekly basis. As the index prices were approaching peak, category managers sent requests for periodic price updates from suppliers using our sourcing solution. This helped buyers to view price changes and lock-in prices when the underlying index prices were trending down.

Reduce SKU complexity – This is a commonly known concept in the procurement world.

Reduce SKU complexity – This is a commonly known concept in the procurement world. But few procurement leaders have actively pursued complexity reduction. However, the current business situation is a ‘trigger’ to work on reducing SKU complexity. Several leaders are actively working to reduce SKU complexity for 2 reasons:

a. Contain cost increases: Companies are consolidating SKUs to increase volume for select SKUs. This helps suppliers to focus on their supply chain while potentially providing price advantages to the buyers.

b. Manage supply risks: Companies are also shifting volume to SKUs which are not affected by supply shortages

Case study 2: With rising prices across several sheet metal parts, an automotive manufacturer decided on a strategy which was different from supplier negotiations. The company collaborated with the supplier to develop a strategy for part consolidation which would help the buyer to contain prices and would help the supplier to streamline their supply chain and capacity planning.

Continue sourcing post -pandemic

Procurement leaders are amazed at prices that non-incumbent suppliers are providing for categories that haven’t been sourced during pandemic. In several categories, procurement leaders are not only able to contain costs but are also able to get savings. Although, the savings realized in this market is typically not close to savings that you would expect in a non-inflationary environment.

Case study 3: An industrial company wanted to source MRO as the incumbent was providing 30% price increase. Conducting an RFQ with multiple suppliers using our sourcing solution identified upto 8% savings in Round 1 from multiple suppliers. Seeing this difference gave confidence to the category manager that they don’t have to take price increases from the incumbent but just move to other suppliers if incumbent continues to propose price increase.

Onshoring

With the recent risks of supply disruptions and uncertainties in trade environment, business leaders are reviewing on-shoring or near shoring to manage risks. For select categories/ industries, the onshore market has disappeared because of continuous prior off-shoring practices. Hence, some procurement leaders are evaluating whether they can invest in on-shore/ near-shore supplier capabilities for a mid-long term relationship.

Market-cost/ should-cost based negotiations

Market-cost/ should-cost based negotiations – The pressure to reduce costs in the fiscal year often pushed procurement leaders to conduct negotiations with incumbents in an inflationary environment. Should-costing was one of the critical methods which helped procurement leaders identify the parameters that can be negotiated with the incumbents, and determine the floor and ceiling for such negotiations. The should-costs were further validated by either direct sourcing or insights from an adjacent category sourcing to finalize the opportunities.

Case study 4: A food packaging company was unsure of the current market conditions and what should they expect from a pricing standpoint. The category manager conducted should-cost analysis for high runner parts and found a 40% gap between current price and should-cost. The should-cost was further validated by a sourcing effort where several suppliers were able to bridge 50% of the should cost gap hence giving 20%+ savings on the high runners.

Make vs buy

Business leaders are continually evaluating make vs buy for products manufactured internally. This helps companies to manage supply risks while only outsourcing those products which are not-competitive to manufacture internally.

The company decided to outsource 40% of the volume to suppliers and keep 60% of the volume internally

Case study 5: An automotive company wanted to outsource stamped parts. However, the company also had an internal stamping operation. Hence the company conducted an RFQ with different suppliers and continually compared internal operations. Overall, the company decided to outsource 40% of the volume to suppliers and keep 60% of the volume internally.

Adopt next-generation technologies

The impact of software across all business functions has been nothing short of revolutionary over the past several decades. Yet somehow, procurement is still underserved by high-quality tools with a friendly user experience. As a result, teams often default back to excel and email (unless they’re forced to use a clunky and brittle SAP installation).

LightSource is radically different, and what many are calling the “next-generation operating system for procurement teams.” With enough time and talent, all of the 6 strategies above are approachable. However, in a world with limited resources, software tools like LightSource empower procurement to do more, be more strategic, while conserving their bandwidth. We work with customers hand-in-hand to effectively implement LightSource, help in developing category strategy and manage the sourcing process as needed. LightSource solution comes with an excellent ‘white glove procurement concierge service’ that is the best combination of software and services in the market.

Ready to change the way you source?

Try out LightSource and you’ll never go back to Excel and email.

Ready to change the way you source?

Try out LightSource and you’ll never go back to Excel and email.

Ready to change the way you source?

Try out LightSource and you’ll never go back to Excel and email.

Trusted by:

Trusted by:

Trusted by:

*GARTNER is a registered trademark and service mark of Gartner, Inc. and/or its affiliates in the U.S. and internationally, and COOL VENDORS is a registered trademark of Gartner, Inc. and/or its affiliates and are used herein with permission. All rights reserved. Gartner does not endorse any vendor, product or service depicted in its research publications, and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner’s research organization and should not be construed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose.