Nov 1, 2021

What is supply chain?

A simple definition for a complex field.

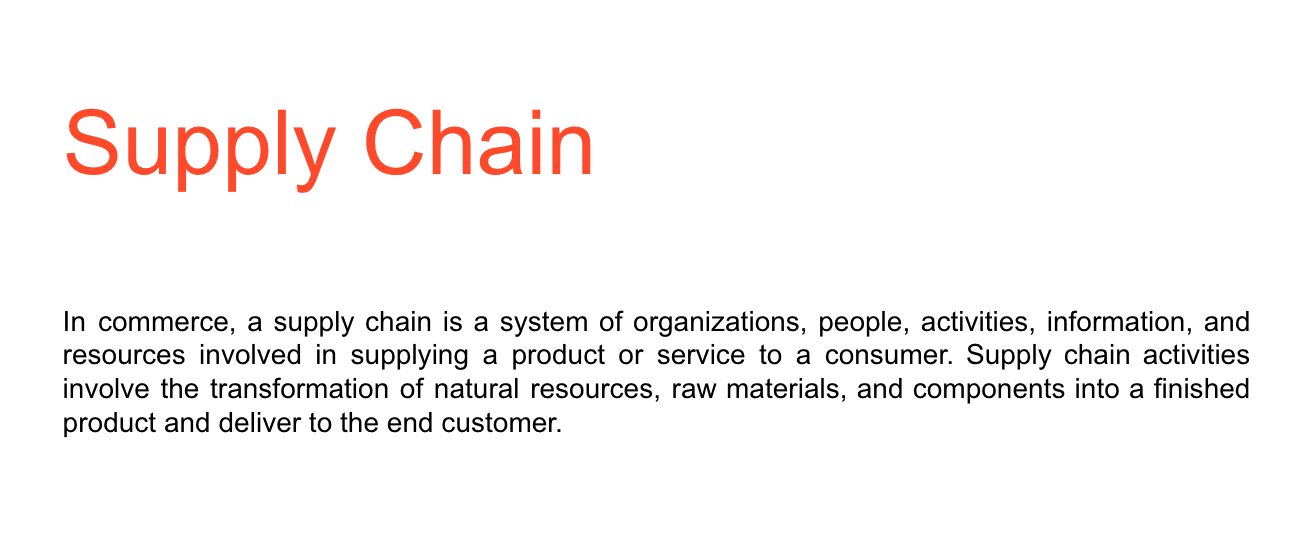

While there is no single definition, this felt like a pretty good one:

The overly simplistic view of "supply chain" is it's just the flow of goods. But that's actually not all. Supply chain is everything involved in the supplying of a product (or service) to a consumer. Moreover, supply chains are not just about "stuff;" they're also about the flow of "information."

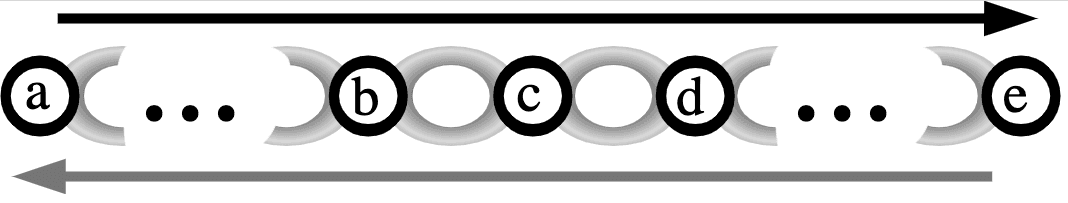

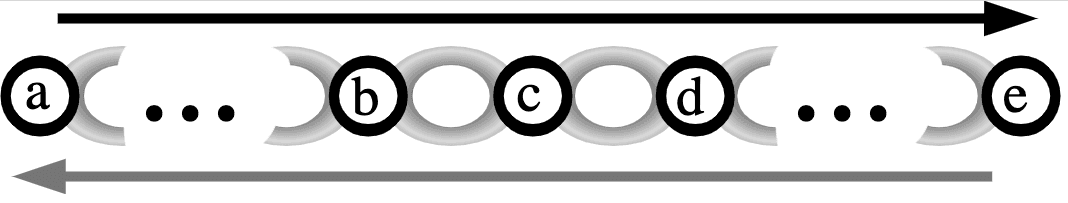

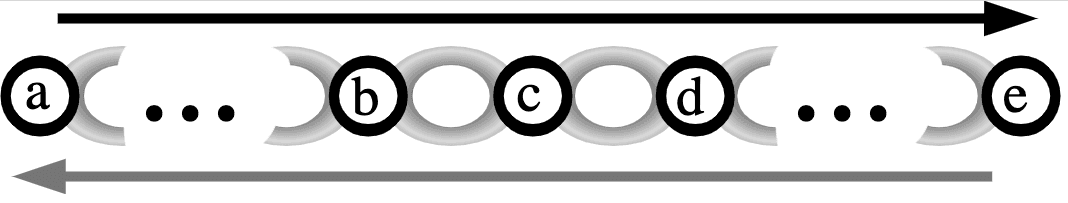

Looking at this linear diagram, the nodes (a through e) are the participants in the chain, for example raw material suppliers, manufacturers, distributors, and customers. The links between the nodes is the flow of goods. Physical things are moving forward (or "downstream") as materials move through the supply chain, as well as "upstream" with backhauls and reverse-logistics. Finally the arrows on top and bottom represent the flow of information. This can include a huge range of interactions around parts, quantities, logistics tracking, quality control, payments, and collaboration across countless fronts.

A goods supply chain without an information supply chain is broken.

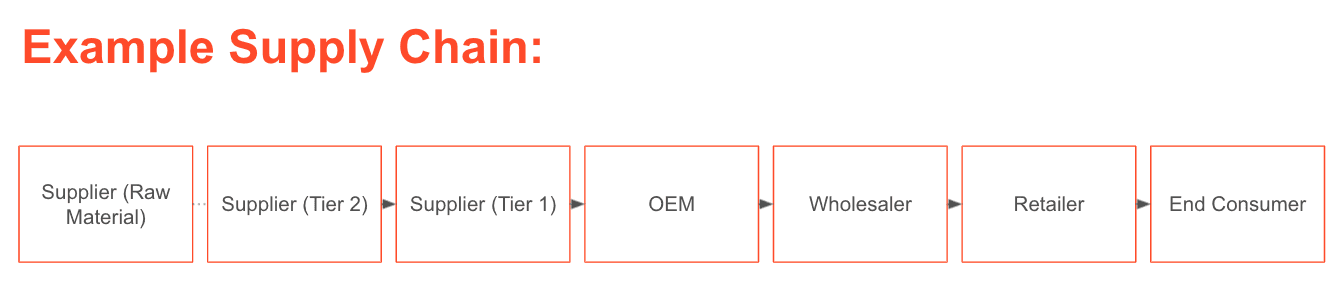

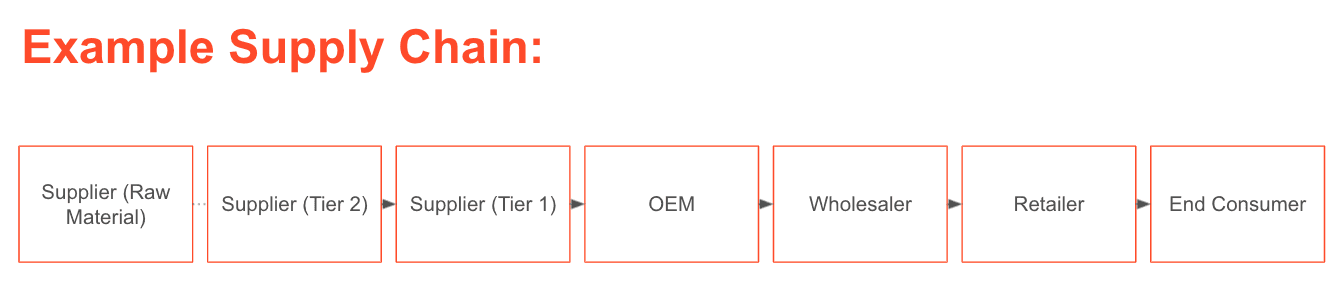

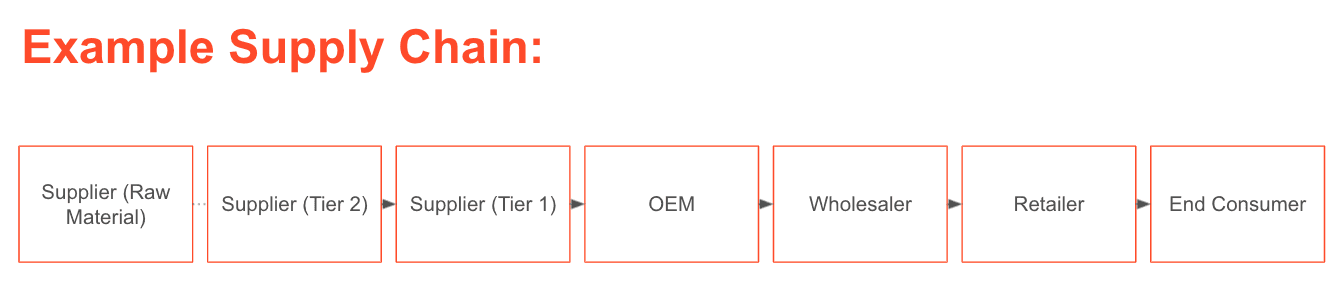

Every supply chain looks different, but below is a standard example of how one might look:

A quick note on lexicon: the OEM is the manufacturer (or assembler) of the final product (e.g. think Tesla). Then the "Tier 1" is the supplier to the OEM. The sub-supplier (or the supplier's supplier) is called the "Tier 2," and so on and so forth.

Supply chain wears many hats

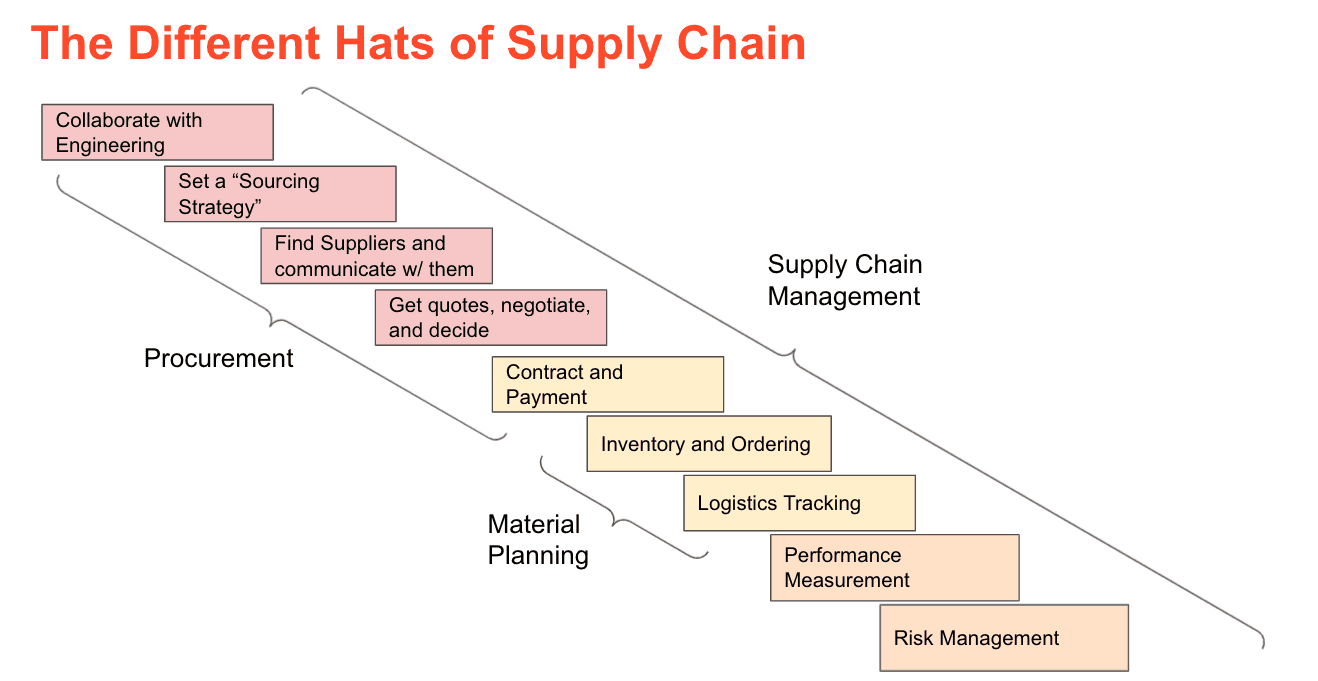

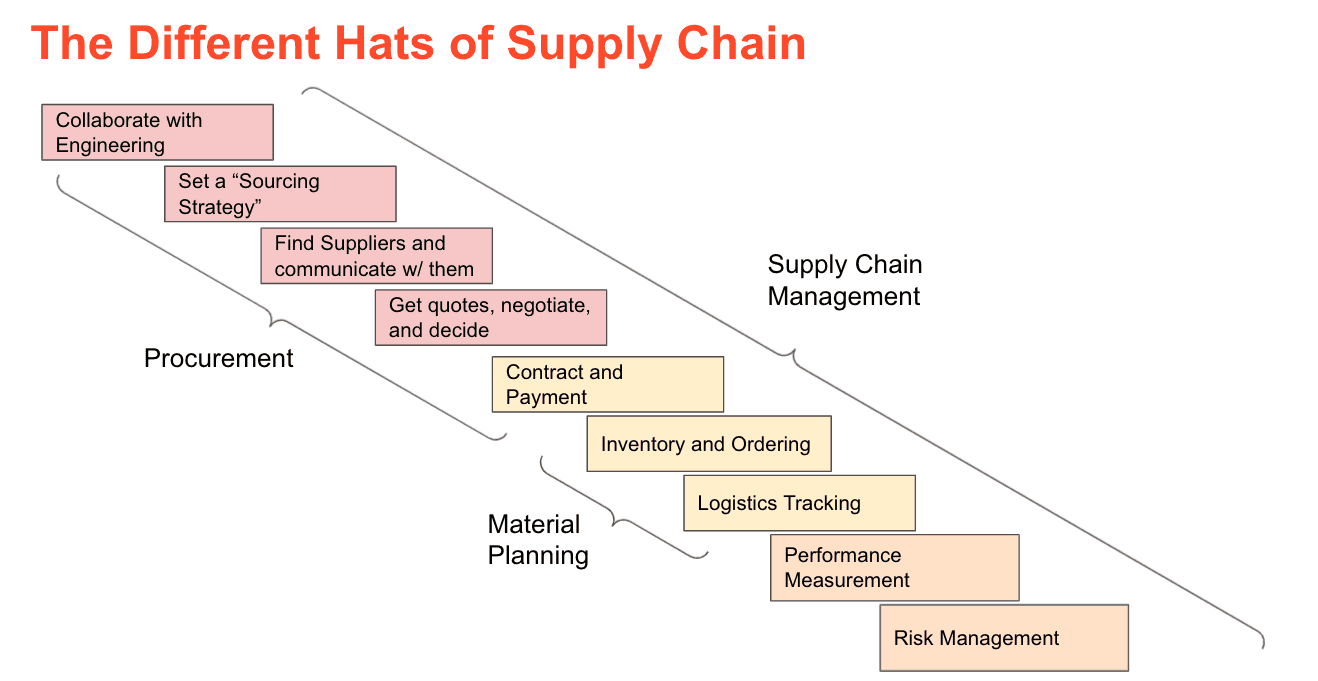

Every organization structures their team in a slightly different way, but supply chain managers have on average one of the most complex and broad jobs in any business.

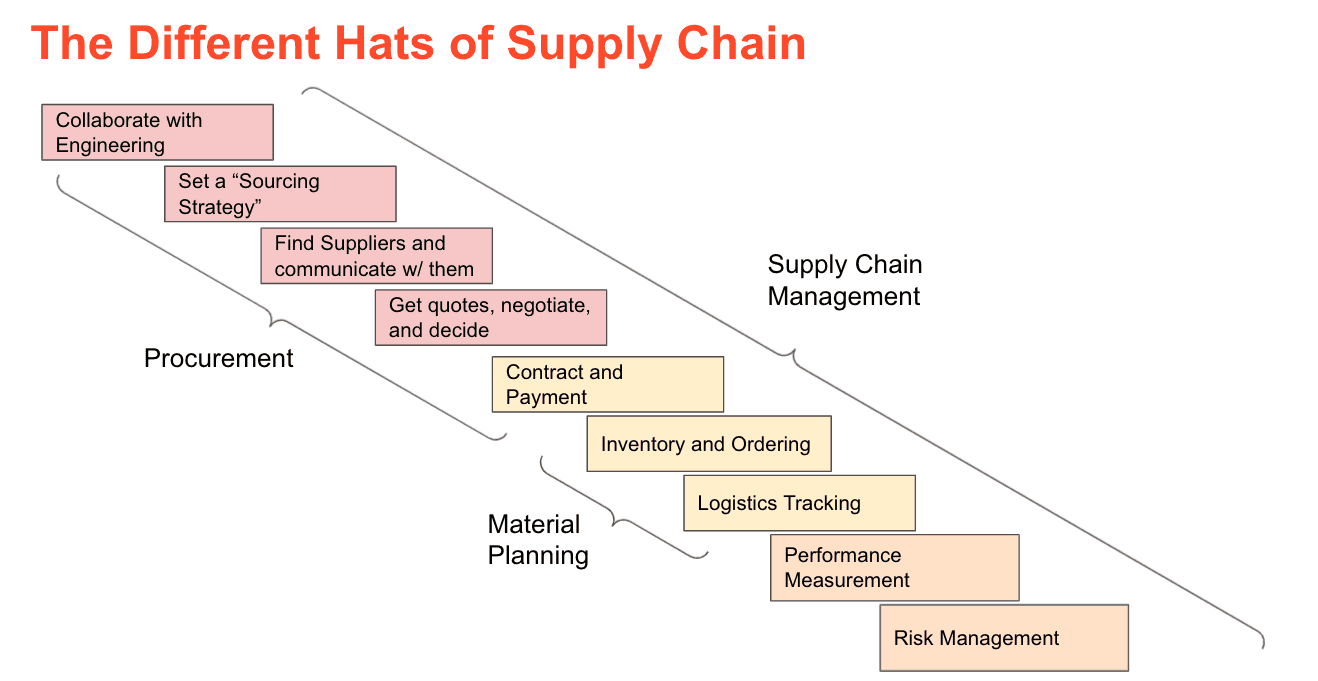

Looking at this diagram now, it's not even fully complete. Supply chain teams have a mix of tasks that run the gamut from collaborating with engineering, to finding and negotiating with suppliers, to working with legal on contracting, down to measuring inventory and risk in the business even through production.

At the big automotive companies, sometimes the jobs will be divided, with dedicated Global Supply Chain managers focused on procurement, Cost Engineers setting targets, Material Planning figuring out inventory and ordering, and Supplier Industrialization Engineers actually getting the Tier 1's up and running.

However, in most companies, especially those with a limited procurement function, the category managers themselves will own 100% of these functions end-to-end.

Purchasing versus sourcing

There have been a huge amount of advancements in the last decade in the procurement field (even though it doesn't always feel like that).

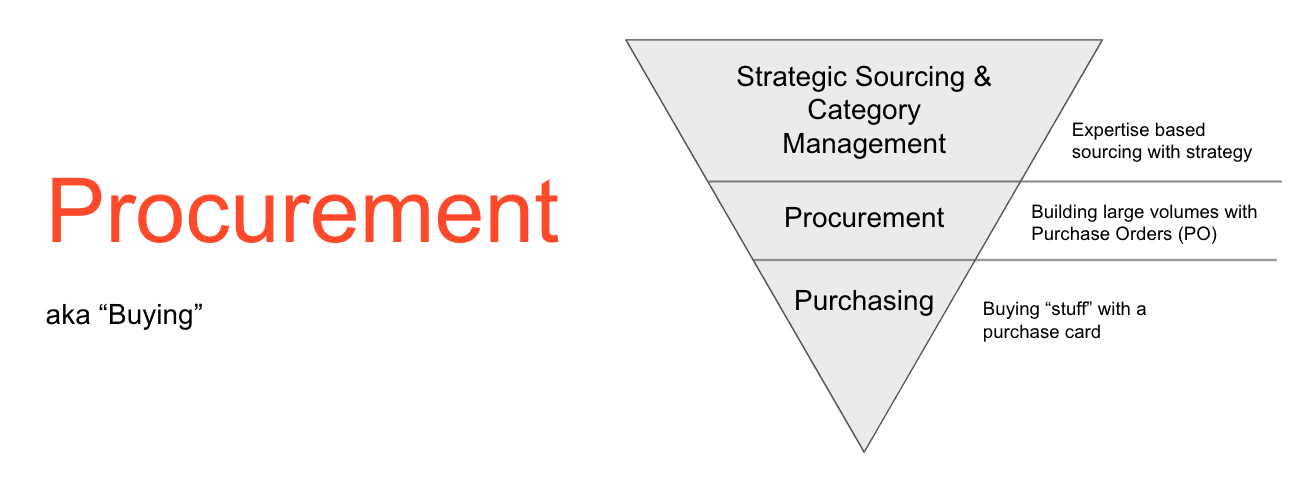

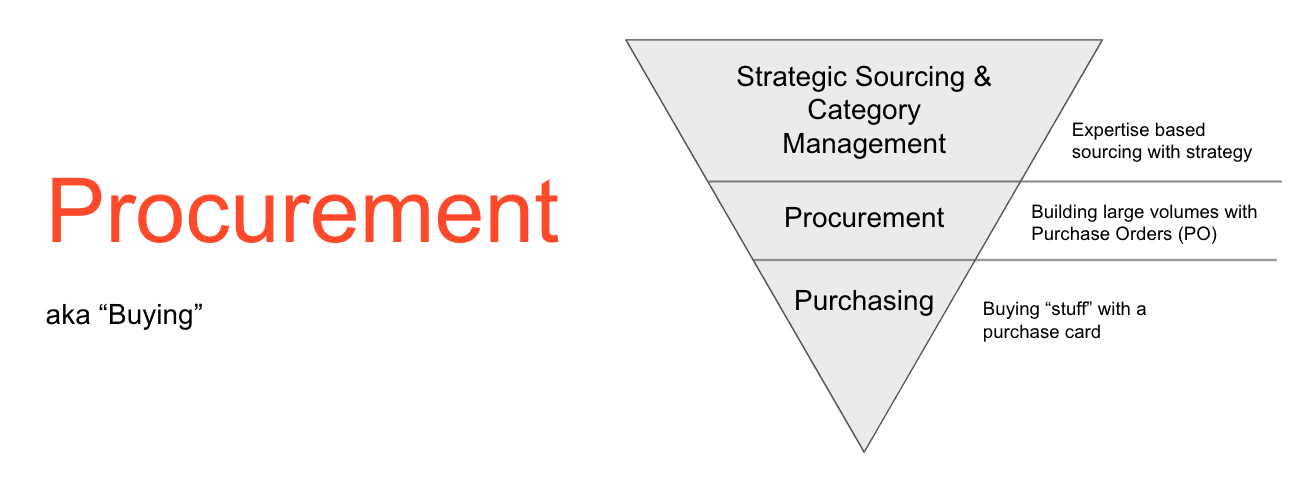

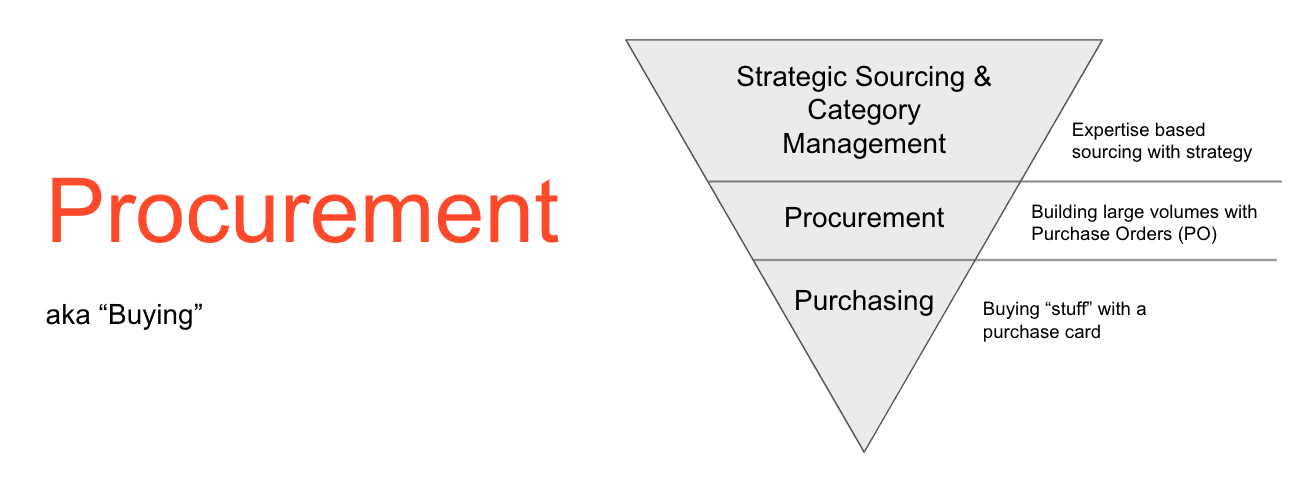

One of the major shifts is actually a change in philosophy and skill-level. In the days of yore, Procurement was just a simple buying function. Purchasing. Place orders, get stuff -- all very transactional.

In the last decade or two, procurement has started to rise in stature. Businesses are (or at least should be) starting to wake up to the idea that without Supply Chain teams, there's nothing to sell. And in this year of COVID specifically, we've seen how best-in-class procurement teams can defy odds to deliver parts even through disruptions.

This chart is somewhat half-baked, but bear with me. At the bottom of the inverted-pyramid, is "purchasing" - the smallest dollars are often bought through a corporate purchase-card. Think about the tail-spend indirect type categories here. One rung above is the procurement professionals, who are buying a larger volume of goods, with more relationships in the mix, using mostly purchase orders (PO's) through the ERP.

And then finally, on top is the bleeding-edge practitioners, disciples of of Strategic Sourcing -- a philosophy that focuses on alignment and relationships. Category Managers in this class bring with them deep expertise, specific to the areas in which they operate. In turn, they are entrusted with the largest amounts of spend and achieve simply unbelievable outcomes.

To learn more, we'd encourage you to read Peter Kraljic's iconic essay: Purchasing Must Become Supply Management.

Look out for future posts diving into more depth on Category Management and Strategic Sourcing.

Digital tools

Ok, you've made it this far, so let me plug our product LightSource.

Software technologies and e-procurement solutions are extremely important to the top-performing procurement teams. So software like LightSource is an extension of the mind's capabilities, helping give procurement managers superpowers and do things that would normally take months in a matter of minutes.

Digital tools can help on a number of fronts (and with the best tools, all of them at once), including: transparency, cost-reduction, executive visibility, supplier relationships and discovery, and frankly overall procurement team happiness. Basically everything a supply chain manager might need to do in day-to-day life.

Software has this special ability to take the boring transactional tasks off peoples' plates and free up their time and attention to focus on the hard strategic or relationship questions that procurement professionals just love.

If you have any questions about LightSource or want to talk procurement generally, don't hesitate to reach out at: contact@lightsource.ai

While there is no single definition, this felt like a pretty good one:

The overly simplistic view of "supply chain" is it's just the flow of goods. But that's actually not all. Supply chain is everything involved in the supplying of a product (or service) to a consumer. Moreover, supply chains are not just about "stuff;" they're also about the flow of "information."

Looking at this linear diagram, the nodes (a through e) are the participants in the chain, for example raw material suppliers, manufacturers, distributors, and customers. The links between the nodes is the flow of goods. Physical things are moving forward (or "downstream") as materials move through the supply chain, as well as "upstream" with backhauls and reverse-logistics. Finally the arrows on top and bottom represent the flow of information. This can include a huge range of interactions around parts, quantities, logistics tracking, quality control, payments, and collaboration across countless fronts.

A goods supply chain without an information supply chain is broken.

Every supply chain looks different, but below is a standard example of how one might look:

A quick note on lexicon: the OEM is the manufacturer (or assembler) of the final product (e.g. think Tesla). Then the "Tier 1" is the supplier to the OEM. The sub-supplier (or the supplier's supplier) is called the "Tier 2," and so on and so forth.

Supply chain wears many hats

Every organization structures their team in a slightly different way, but supply chain managers have on average one of the most complex and broad jobs in any business.

Looking at this diagram now, it's not even fully complete. Supply chain teams have a mix of tasks that run the gamut from collaborating with engineering, to finding and negotiating with suppliers, to working with legal on contracting, down to measuring inventory and risk in the business even through production.

At the big automotive companies, sometimes the jobs will be divided, with dedicated Global Supply Chain managers focused on procurement, Cost Engineers setting targets, Material Planning figuring out inventory and ordering, and Supplier Industrialization Engineers actually getting the Tier 1's up and running.

However, in most companies, especially those with a limited procurement function, the category managers themselves will own 100% of these functions end-to-end.

Purchasing versus sourcing

There have been a huge amount of advancements in the last decade in the procurement field (even though it doesn't always feel like that).

One of the major shifts is actually a change in philosophy and skill-level. In the days of yore, Procurement was just a simple buying function. Purchasing. Place orders, get stuff -- all very transactional.

In the last decade or two, procurement has started to rise in stature. Businesses are (or at least should be) starting to wake up to the idea that without Supply Chain teams, there's nothing to sell. And in this year of COVID specifically, we've seen how best-in-class procurement teams can defy odds to deliver parts even through disruptions.

This chart is somewhat half-baked, but bear with me. At the bottom of the inverted-pyramid, is "purchasing" - the smallest dollars are often bought through a corporate purchase-card. Think about the tail-spend indirect type categories here. One rung above is the procurement professionals, who are buying a larger volume of goods, with more relationships in the mix, using mostly purchase orders (PO's) through the ERP.

And then finally, on top is the bleeding-edge practitioners, disciples of of Strategic Sourcing -- a philosophy that focuses on alignment and relationships. Category Managers in this class bring with them deep expertise, specific to the areas in which they operate. In turn, they are entrusted with the largest amounts of spend and achieve simply unbelievable outcomes.

To learn more, we'd encourage you to read Peter Kraljic's iconic essay: Purchasing Must Become Supply Management.

Look out for future posts diving into more depth on Category Management and Strategic Sourcing.

Digital tools

Ok, you've made it this far, so let me plug our product LightSource.

Software technologies and e-procurement solutions are extremely important to the top-performing procurement teams. So software like LightSource is an extension of the mind's capabilities, helping give procurement managers superpowers and do things that would normally take months in a matter of minutes.

Digital tools can help on a number of fronts (and with the best tools, all of them at once), including: transparency, cost-reduction, executive visibility, supplier relationships and discovery, and frankly overall procurement team happiness. Basically everything a supply chain manager might need to do in day-to-day life.

Software has this special ability to take the boring transactional tasks off peoples' plates and free up their time and attention to focus on the hard strategic or relationship questions that procurement professionals just love.

If you have any questions about LightSource or want to talk procurement generally, don't hesitate to reach out at: contact@lightsource.ai

While there is no single definition, this felt like a pretty good one:

The overly simplistic view of "supply chain" is it's just the flow of goods. But that's actually not all. Supply chain is everything involved in the supplying of a product (or service) to a consumer. Moreover, supply chains are not just about "stuff;" they're also about the flow of "information."

Looking at this linear diagram, the nodes (a through e) are the participants in the chain, for example raw material suppliers, manufacturers, distributors, and customers. The links between the nodes is the flow of goods. Physical things are moving forward (or "downstream") as materials move through the supply chain, as well as "upstream" with backhauls and reverse-logistics. Finally the arrows on top and bottom represent the flow of information. This can include a huge range of interactions around parts, quantities, logistics tracking, quality control, payments, and collaboration across countless fronts.

A goods supply chain without an information supply chain is broken.

Every supply chain looks different, but below is a standard example of how one might look:

A quick note on lexicon: the OEM is the manufacturer (or assembler) of the final product (e.g. think Tesla). Then the "Tier 1" is the supplier to the OEM. The sub-supplier (or the supplier's supplier) is called the "Tier 2," and so on and so forth.

Supply chain wears many hats

Every organization structures their team in a slightly different way, but supply chain managers have on average one of the most complex and broad jobs in any business.

Looking at this diagram now, it's not even fully complete. Supply chain teams have a mix of tasks that run the gamut from collaborating with engineering, to finding and negotiating with suppliers, to working with legal on contracting, down to measuring inventory and risk in the business even through production.

At the big automotive companies, sometimes the jobs will be divided, with dedicated Global Supply Chain managers focused on procurement, Cost Engineers setting targets, Material Planning figuring out inventory and ordering, and Supplier Industrialization Engineers actually getting the Tier 1's up and running.

However, in most companies, especially those with a limited procurement function, the category managers themselves will own 100% of these functions end-to-end.

Purchasing versus sourcing

There have been a huge amount of advancements in the last decade in the procurement field (even though it doesn't always feel like that).

One of the major shifts is actually a change in philosophy and skill-level. In the days of yore, Procurement was just a simple buying function. Purchasing. Place orders, get stuff -- all very transactional.

In the last decade or two, procurement has started to rise in stature. Businesses are (or at least should be) starting to wake up to the idea that without Supply Chain teams, there's nothing to sell. And in this year of COVID specifically, we've seen how best-in-class procurement teams can defy odds to deliver parts even through disruptions.

This chart is somewhat half-baked, but bear with me. At the bottom of the inverted-pyramid, is "purchasing" - the smallest dollars are often bought through a corporate purchase-card. Think about the tail-spend indirect type categories here. One rung above is the procurement professionals, who are buying a larger volume of goods, with more relationships in the mix, using mostly purchase orders (PO's) through the ERP.

And then finally, on top is the bleeding-edge practitioners, disciples of of Strategic Sourcing -- a philosophy that focuses on alignment and relationships. Category Managers in this class bring with them deep expertise, specific to the areas in which they operate. In turn, they are entrusted with the largest amounts of spend and achieve simply unbelievable outcomes.

To learn more, we'd encourage you to read Peter Kraljic's iconic essay: Purchasing Must Become Supply Management.

Look out for future posts diving into more depth on Category Management and Strategic Sourcing.

Digital tools

Ok, you've made it this far, so let me plug our product LightSource.

Software technologies and e-procurement solutions are extremely important to the top-performing procurement teams. So software like LightSource is an extension of the mind's capabilities, helping give procurement managers superpowers and do things that would normally take months in a matter of minutes.

Digital tools can help on a number of fronts (and with the best tools, all of them at once), including: transparency, cost-reduction, executive visibility, supplier relationships and discovery, and frankly overall procurement team happiness. Basically everything a supply chain manager might need to do in day-to-day life.

Software has this special ability to take the boring transactional tasks off peoples' plates and free up their time and attention to focus on the hard strategic or relationship questions that procurement professionals just love.

If you have any questions about LightSource or want to talk procurement generally, don't hesitate to reach out at: contact@lightsource.ai

Ready to change the way you source?

Try out LightSource and you’ll never go back to Excel and email.

Ready to change the way you source?

Try out LightSource and you’ll never go back to Excel and email.

Ready to change the way you source?

Try out LightSource and you’ll never go back to Excel and email.

Trusted by:

Trusted by:

Trusted by:

*GARTNER is a registered trademark and service mark of Gartner, Inc. and/or its affiliates in the U.S. and internationally, and COOL VENDORS is a registered trademark of Gartner, Inc. and/or its affiliates and are used herein with permission. All rights reserved. Gartner does not endorse any vendor, product or service depicted in its research publications, and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner’s research organization and should not be construed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose.